Race finishing

Superfinishing of antifriction bearings

Inner and outer rings

The world of rolling bearings is almost endless. From the gigantic bearings of offshore wind turbines to the micro bearings of the smallest variable displacement motors in our cars, a wide variety of shapes and sizes are used.

Whether small batch production or series production in flexible production lines, we can supply you with the most suitable machine for processing your surface requirements, including complete automation.

Supfina always provides the appropriate solution for the perfect surface.

- Deep groove ball bearings

- Angular ball bearings

- Cylindrical roller bearings

- Tapered roller bearings

- Self-aligning roller bearings

New Supfina RaceX

The X for more

Speed, Precision, and Modularity

A system that grows, adapts, and redefines productivity – for the efficient superfinishing of all types of rolling bearing rings.

Developed based on years of experience, the RaceX sets new standards in the superfinishing of rolling bearings. Its modular design allows for flexible adaptation to a wide range of requirements. Reduced idle times lead to shorter cycle times, increasing productivity.

The RaceX supports the following superfinishing processes:

- Ball bearing raceways

- Roller bearing raceways

- Lips

- Outer diameters

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

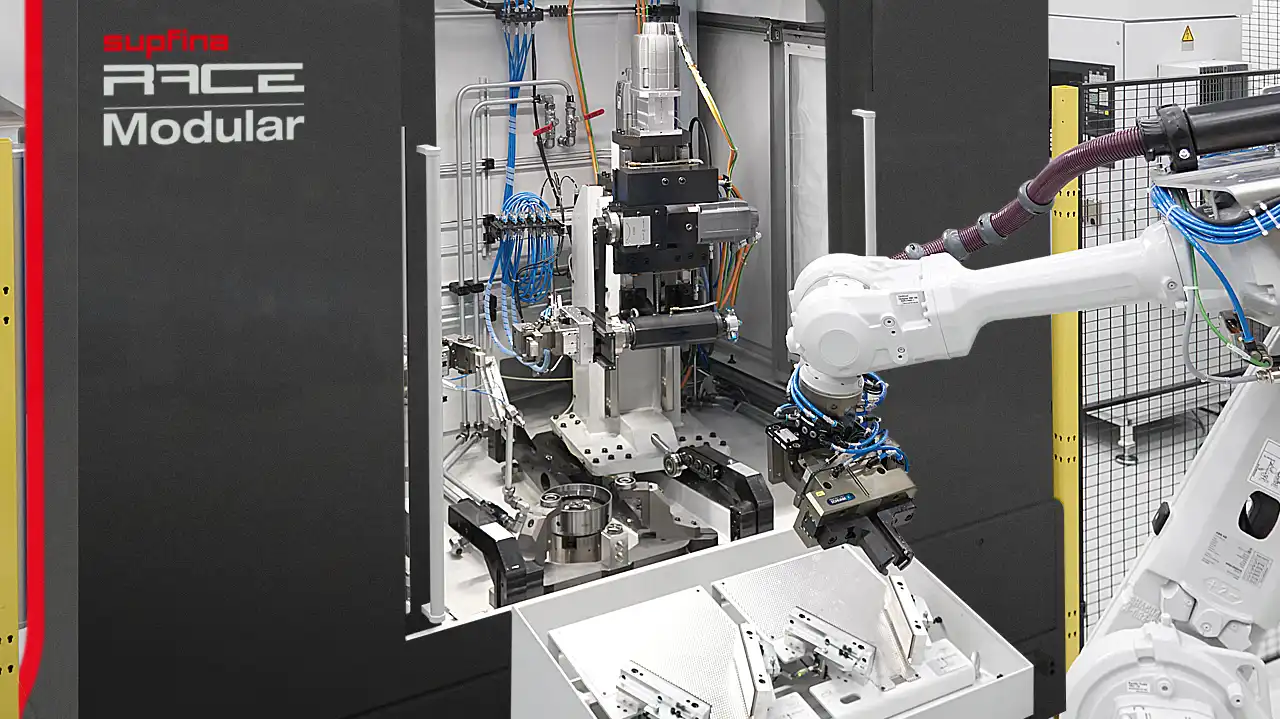

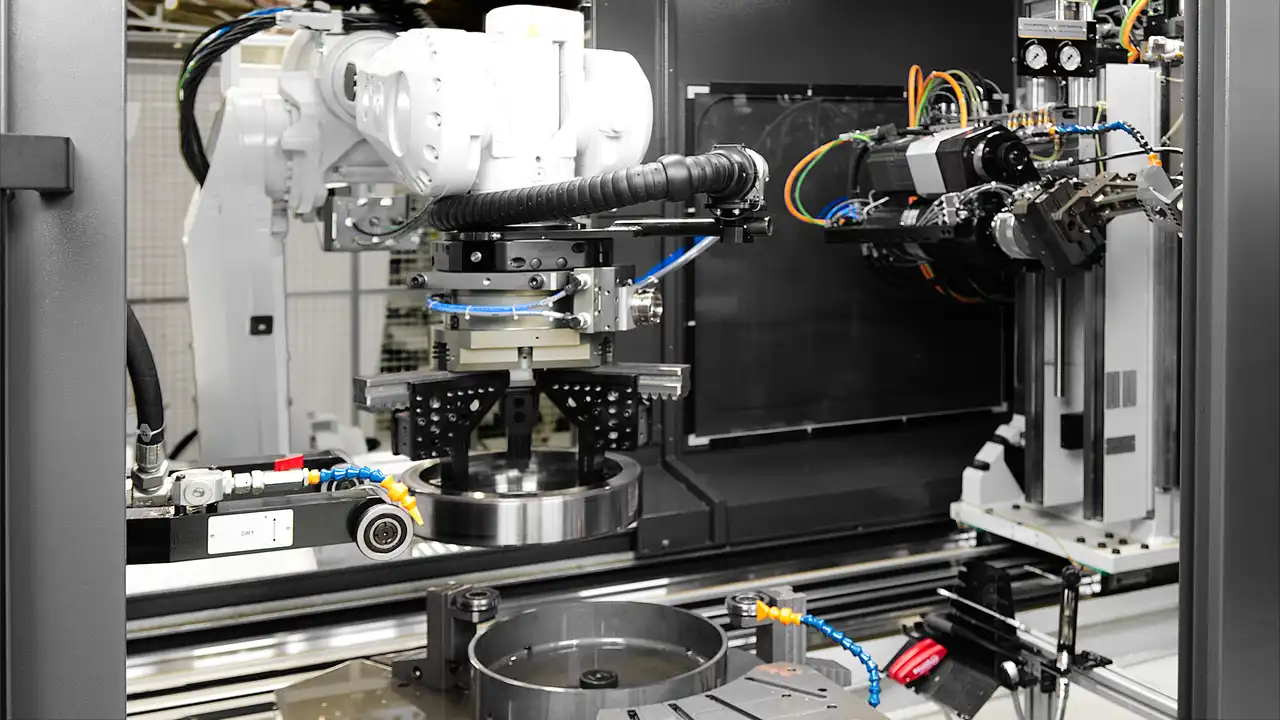

Autonomous production

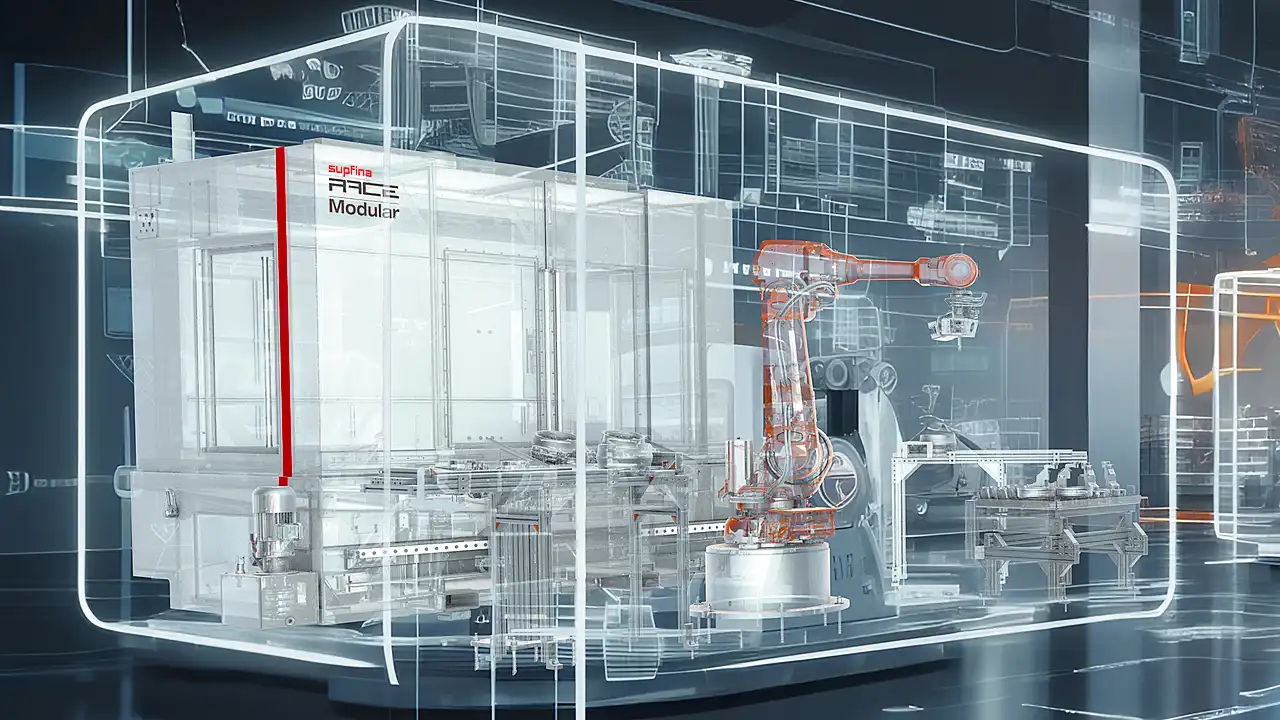

Race Modular

The future of the rolling bearing industry lies in the autonomous use of production machines. In very close cooperation with our customers, the Supfina Race Modular system solution has been systematically developed for the autonomous and unmanned superfinishing of rolling bearings.

All key production processes are automated and run 24/7 without an operator:

- Batch change

- Mechanical set-up process

- Tool change

- Finishing stone change in production

- Component handling

- Control through production line

The Supfina Race Modular offers all the advantages of autonomous 24/7 production without an operator:

- Higher production capacity utilization

- Faster order processing and therefore cost and time savings

- Precision and flexibility

- Increased productivity

- Work safety

- Scalability

Thanks to its integration into the IT infrastructure, the Supfina Race Modular offers flexible adaptability to the dynamic processes of the entire production line.

Race

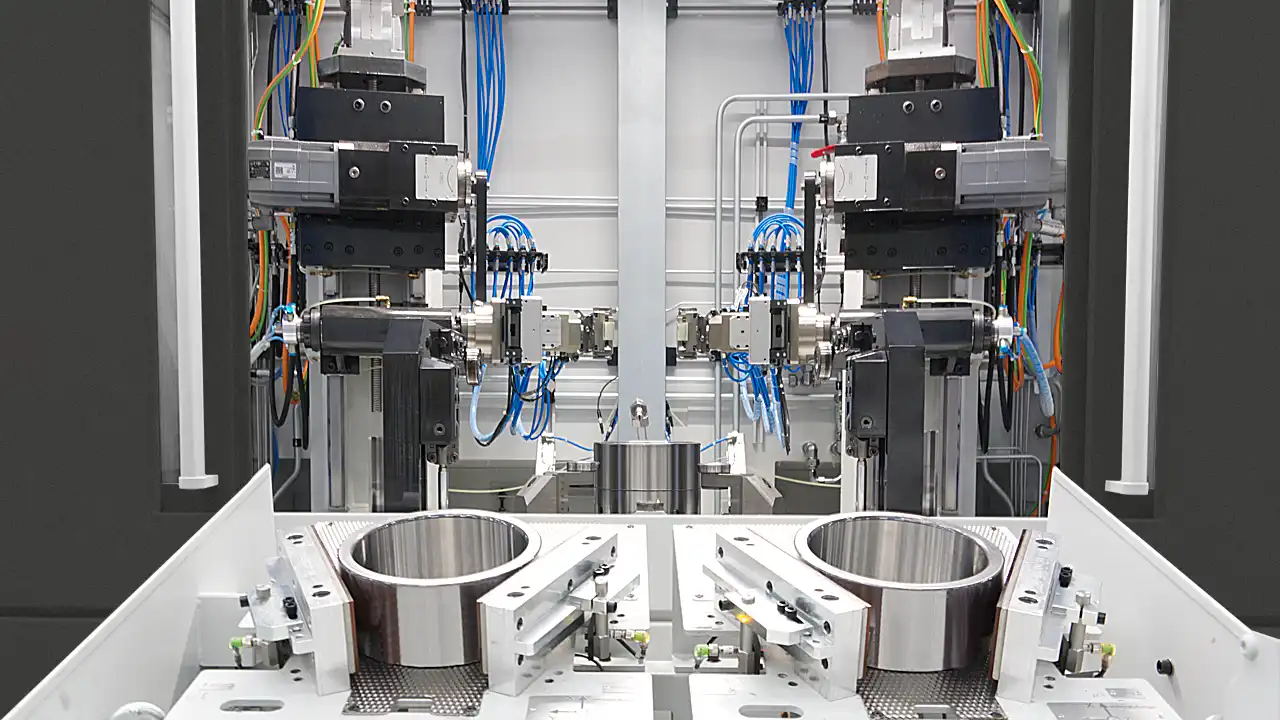

Specialist of the series

The innovative Supfina Race is setting new standards in Superfinishing ball bearing inner and outer rings.

It has been optimized to meet the highest productivity demands, while achieving best quality results, fast set-up times and superior reliability.

- Automatic loading and unloading

- Multi-step process with automatic sequence

- Stone and tape machining can be combined

- Minimized loading times

- Set-up times < 15 minutes

- Optimum accessibility

- State-of-the-art controller system with a technology memory

| Technical data | |

| Working stations | 2 |

| Workpiece diameters | 62 – 160 mm |

| Workpiece width up to | 65 mm |

| Contact angle | 0 – 55° |

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

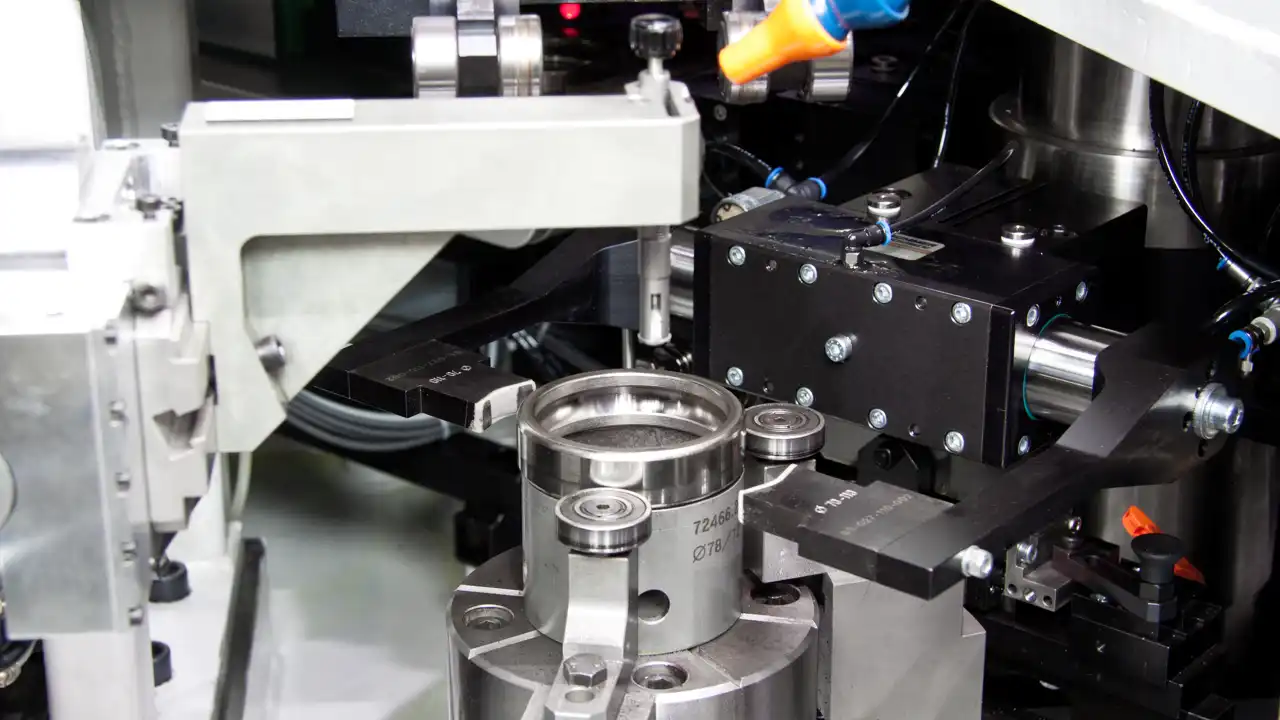

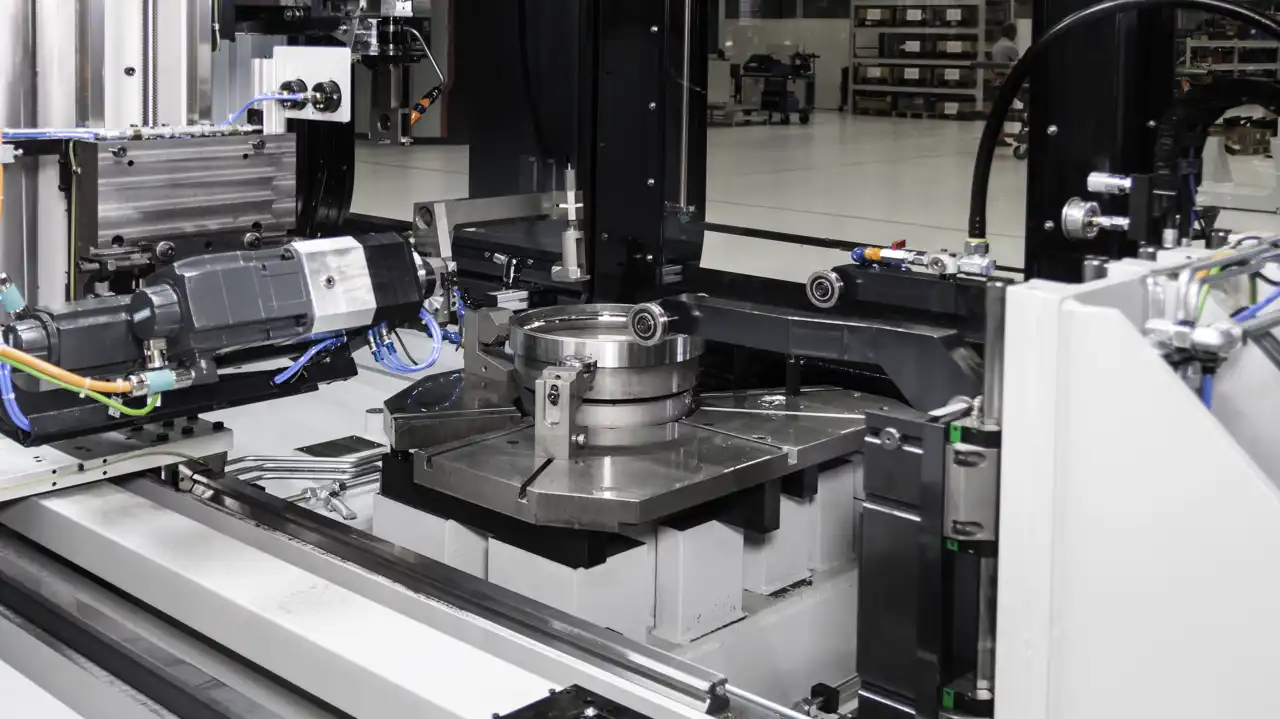

RaceNeo

Cost-effectiveness through robot handling

Flexibility, reliability, safety and highest machining quality have always been the values of the Supfina machines Race, RacePro and RaceFlex.

The new Supfina RaceNeo combines these values with the demand for highest machining quality and increasing requirements regarding economic efficiency in series production at the same time.

- Shortest non-productive times and safe loading due to integrated robot

- Small footprint and compact design

- Easy integration into automated production lines

- Modular adaptation of workpiece holder

- Proven core components

| Workpiece data | |

| Workpiece diameter max Size A | 100 mm |

| Workpiece diameter max Size B | 200 mm |

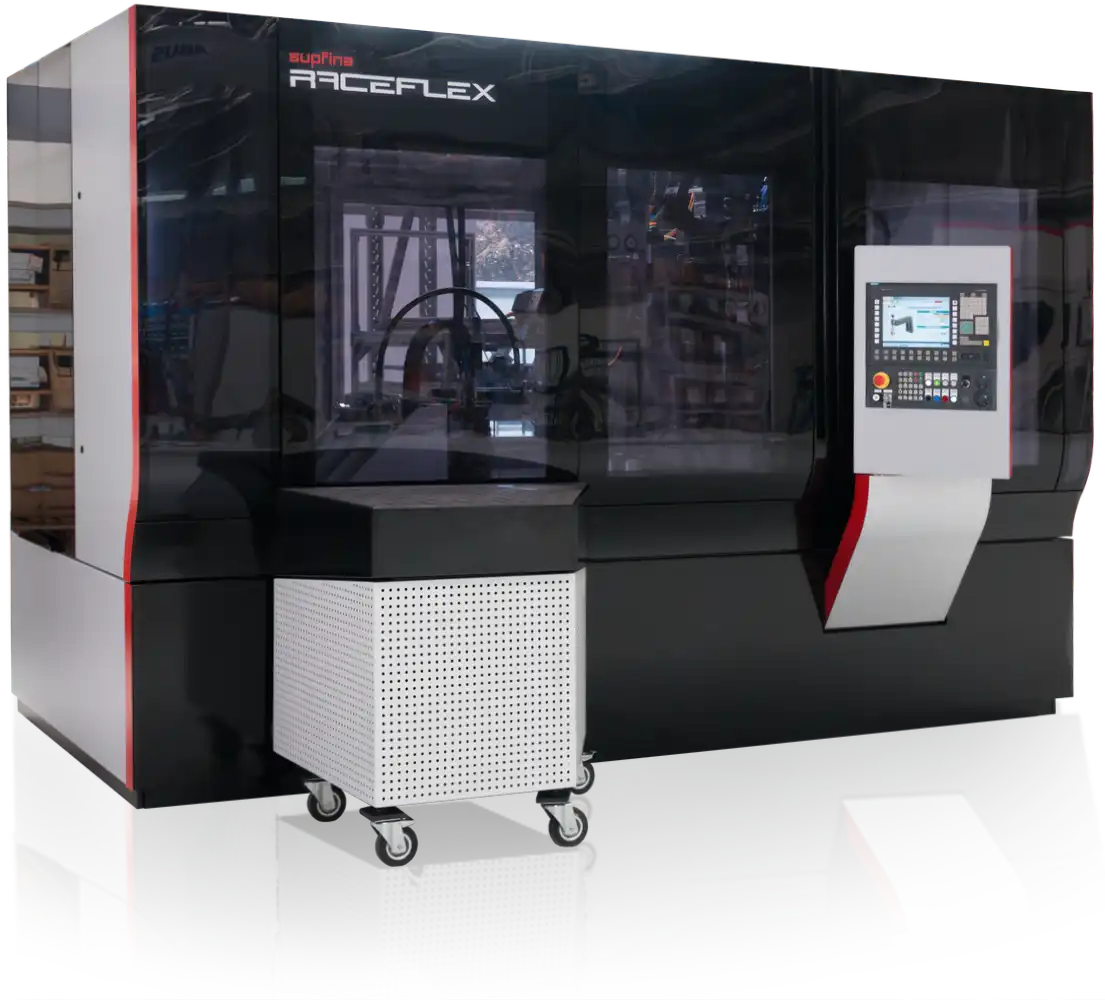

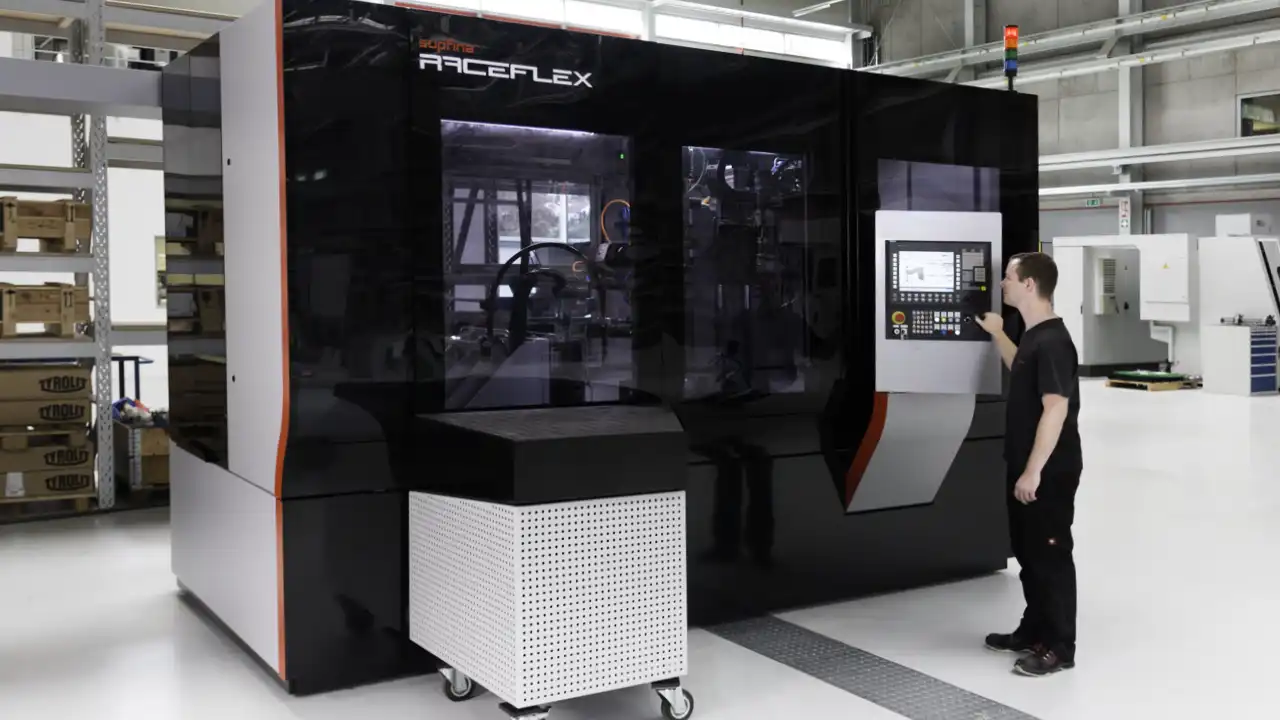

RaceFlex

Flexibility for small-scale production

The Supfina RaceFlex can consistently produce rolling bearing races of the highest quality with maximum adaptability, even for prototypes or small-scale production.

A combination of up to four different superfinishing units allows almost limitless flexibility

- The greatest possible flexibility when machining any raceway geometries

- The highest quality is easily achieved, even for small batches and single parts

- Creation of a surface with a high load-bearing capacity and good lubricating properties

- Improved tool life

- Ideal for small and medium batches

- Production flexibility makes it a sound investment

| Workpiece data | |

| Diameter | Width |

| 30 – 200 mm | 5 – 75 mm |

| 50 – 650 mm | 8 – 100 mm |

| 100 – 800 mm | 20 – 200 mm |

| 600 – 1600 mm | 50 – 500 mm |

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

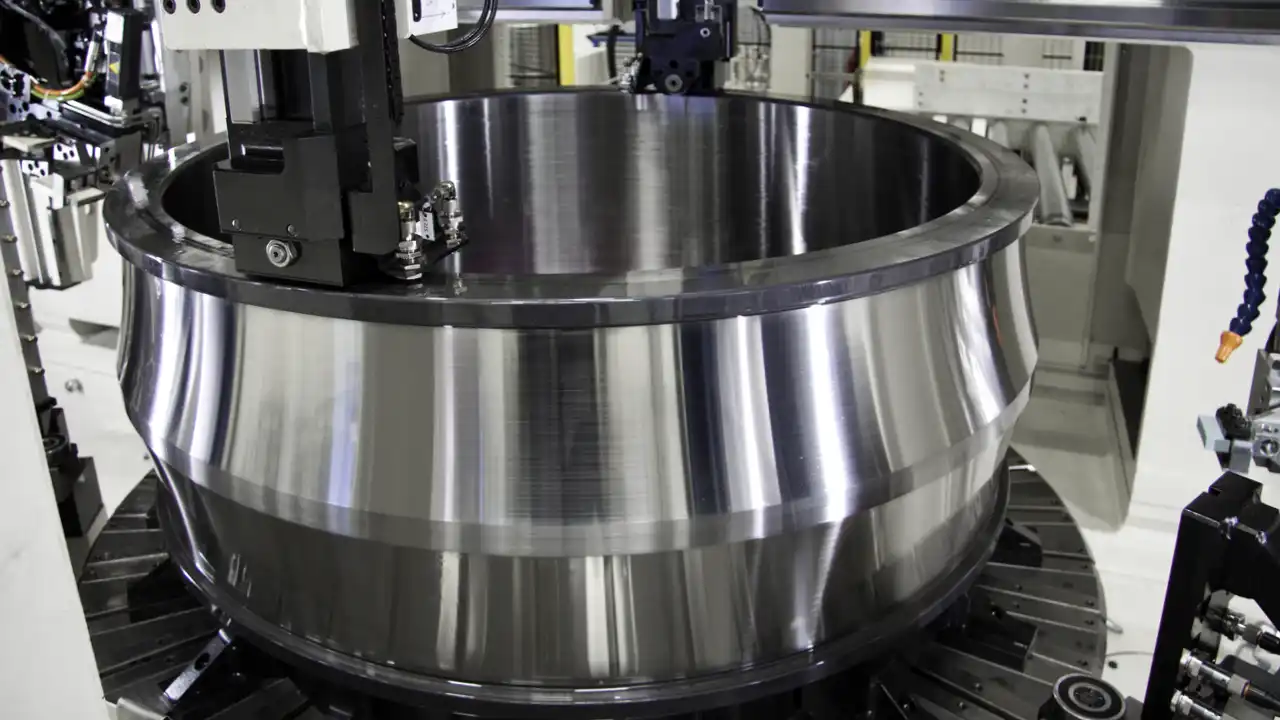

RacePro

Superfinishing in mega format

Even the largest rolling bearing rings require superfinishing of the raceways to withstand the high stresses. The Supfina RacePro is specially designed for the flexible superfinishing of large rings. The design of the machine allows loading by overhead crane or by roller conveyor from the front and rear.

The inner and outer rings of large rolling bearings are required in a wide variety of applications, such as:

- Wind turbines

- Cranes

- Helicopters

ShapePro

Precise profiling of

superfinishing stones

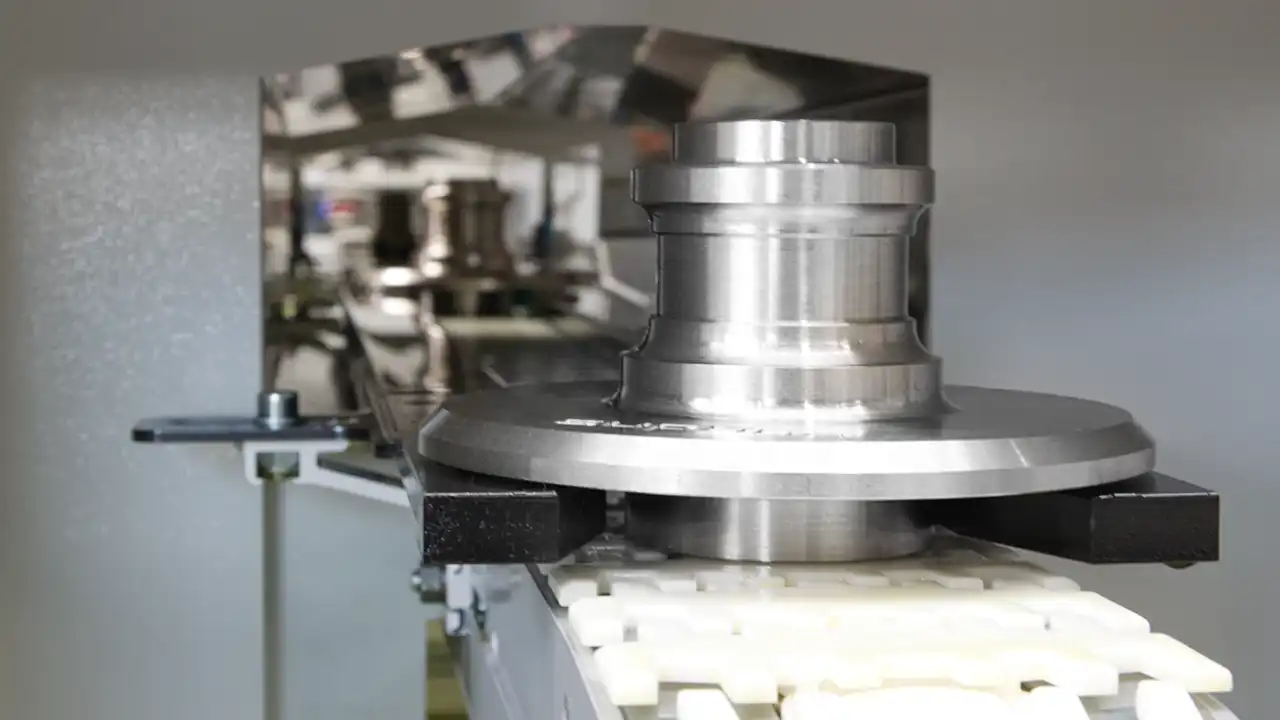

Equipped with the latest CNC technology, the Supfina ShapePro enables precise and repeatable profiling of superfinishing stones. This ensures perfect results every time.

Specially designed for the demanding task of profiling superfinishing stones in rolling bearing production, the Supfina ShapePro is an indispensable solution for the highest precision requirements.

- CNC-controlled precision profiling

- Advanced data memory for fast retrieval of complex shape specifications

- Versatile shaping: concave, convex and complex profiles

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Supfina solutions for raceway machining

Supfina Race

Raceway machining of antifriction bearings Inner and outer rings – Supfina Race

- Automatic loading and unloading

- Multi-step process with automatic sequence

- Stone and tape machining can be combined

- Minimized loading times

- Set-up times < 15 minutes

- Optimum accessibility

- State-of-the-art controler system with a technology memory

Supfina Race

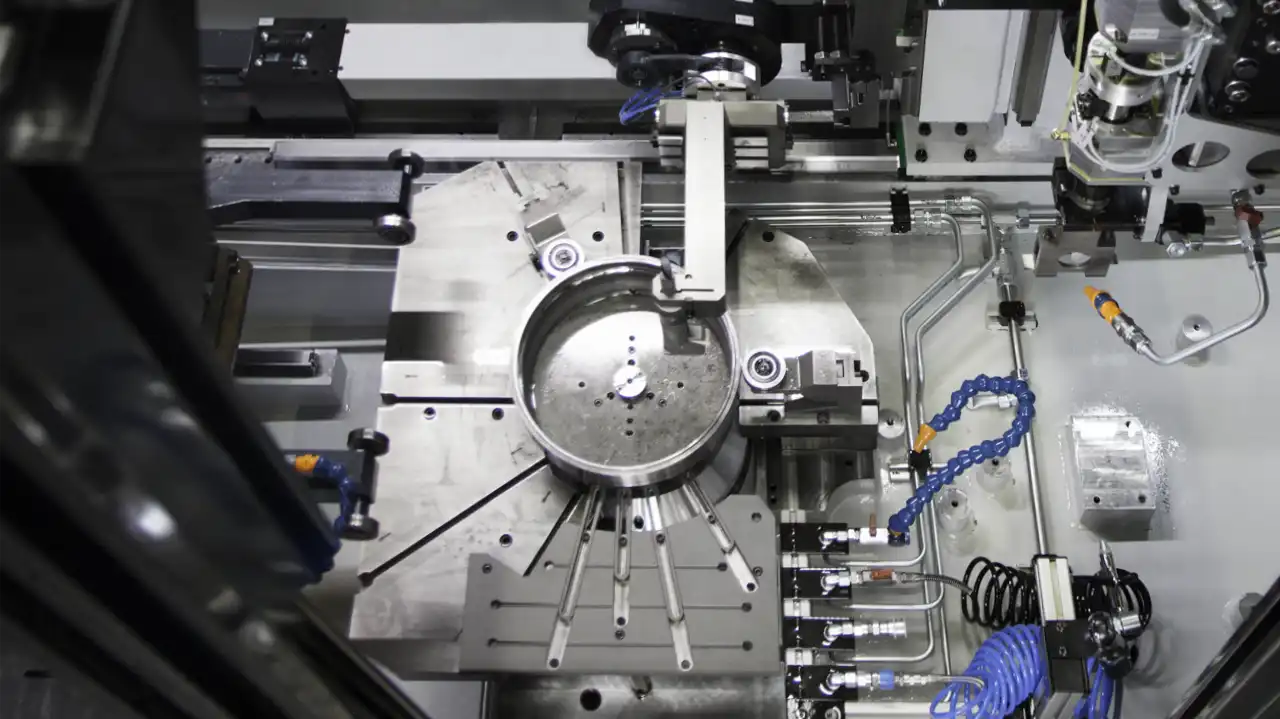

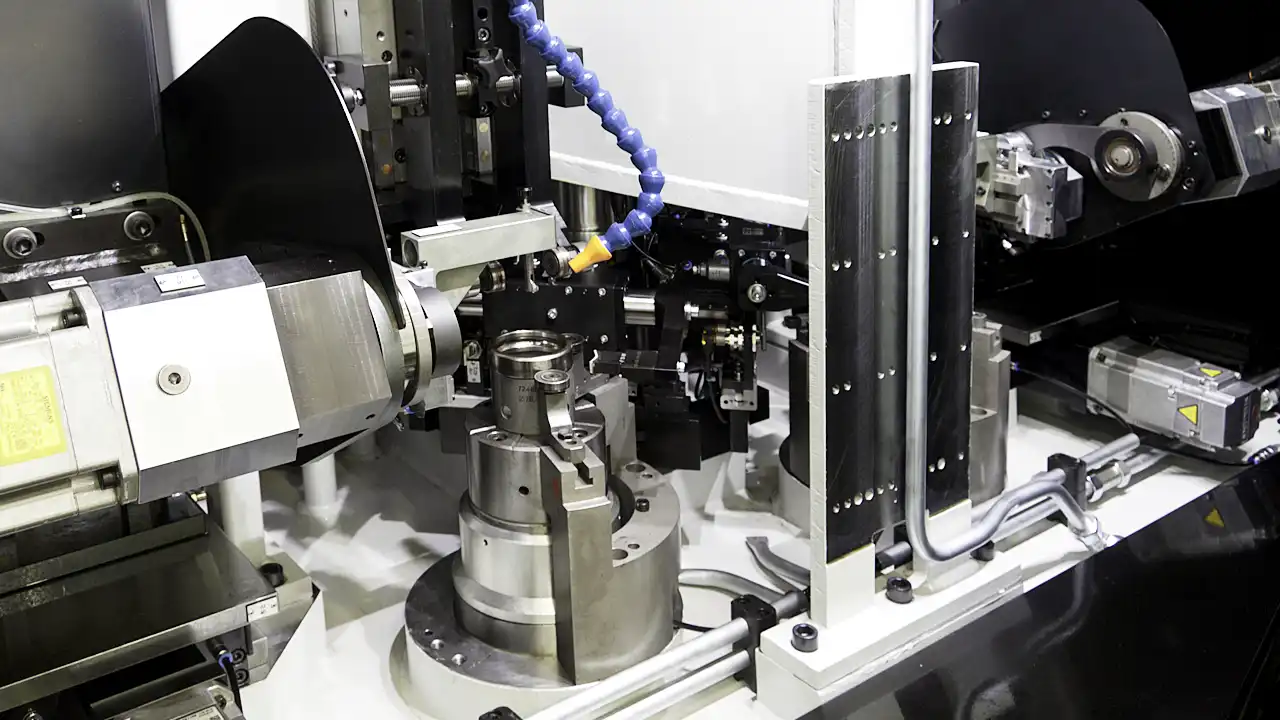

Superfinishing of raceways with stone

The self-centering workpiece fixture and the oscillating unit specially designed by Supfina ensure maximum precision and outstanding durability.

Supfina Race

Two machining stations and two stations for loading and unloading are interconnected via a rotary table, ensuring minimum non-productive times and maximum process reliability.

Supfina Race

The processing stations can be used for pre-finishing and finishing or, after finishing, e.g. for coil processing.

Supfina RaceFlex

The Supfina RaceFlex is made for superfinishing of ball and roller bearings inner and outer rings.

- The greatest possible flexibility when machining any raceway geometries

- The highest quality is easily achieved, even for small batches and single parts

- Creation of a surface with a high load-bearing capacity and good lubricating properties

- Improved tool life

- Quick setup

- Few spare parts

- Ideal for small and medium batches

- Production flexibility makes it a sound investment

Supfina RaceFlex

The highest productivity can be reached through robot-assisted loading and unloading.

Supfina RaceFlex

The RaceFlex can be loaded from above with a crane or gantry loader as well as from the front and rear, manually or by automation.

Supfina RaceNeo

Supfina RaceNeo for superfinishing of bearings

- Shortest non-productive times and safe loading due to integrated robot

- Small footprint and compact design

- Easy integration into automated production lines

- Modular adaptation of workpiece holder

- Proven core components

Supfina RaceNeo

Robot-assisted loading and unloading have significantly maximized productivity while achieving the highest quality results, fast setup times and outstanding reliability.

Are you looking for the right and economical solution for your manufacturing processes?

Deutsch

Deutsch  North America

North America  Français

Français  简体中文(中国)

简体中文(中国)