Economical Fine Grinding

with proven Supfina precision

No matter your workpiece properties, the Supfina Spiro offers an ideal fine grinding solution for your most stringent tolerance and material requirements.

We work closely with you to determine your wants and needs and fine a solution based on your budget. Precision without compromise, it’s our lifelong promise.

Neuheit Supfina Spiro F5 Sense

Technology that thinks for itself

for perfect grinding results

processes demand the highest levels of accuracy and process reliability – especially when dealing with brittle-hard or ultra-thin components. The Spiro F5 Sense sets a new benchmark in this field: thanks to its sensitive “Sense” function, the tool contact force is reduced to below 10 dN, significantly minimizing the risk of edge chipping on the workpiece.

Whether in medical technology, aerospace, or precision engineering – the machine delivers reproducible micrometer-level results, even with challenging materials.

- Sense function: sensitive tool approach

- Gap loading and short stroke lift

- Flexible automation options

- Sharpening programs and sharpening intervals

- Compact footprint

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Spiro line

Key features

- High drive performance

- Maximum flexibility for many applications

- Individually customizable for optimal machining results

- Reduced tool wear thanks to the low-vibration machine stand and guard

- High-precision, noncontact measurement control

- Visual process control for consistently high precision

- User-friendly and intuitive operation

- Great accessibility

- Replacement of the lapping process to increase the efficiency of the process chain

Spiro F5

Compact design, great performance

The Supfina Spiro F5 was specially developed for fine grinding smaller workpieces that require highly precise plane parallelism. It’s the perfect fit for your needs.

- 100-program storage

- Integrated sharpening programs

- Up to seven process cycles

- Optional loading table

| Technical data | |

| Wheel diameter | 445 / 475 mm |

| Ring width | 120 / 150 mm |

| Maximum pressure | 300 daN |

| Workpiece diameter | 4 – 150 mm |

| Workpiece thickness | 0,3 – 50 mm |

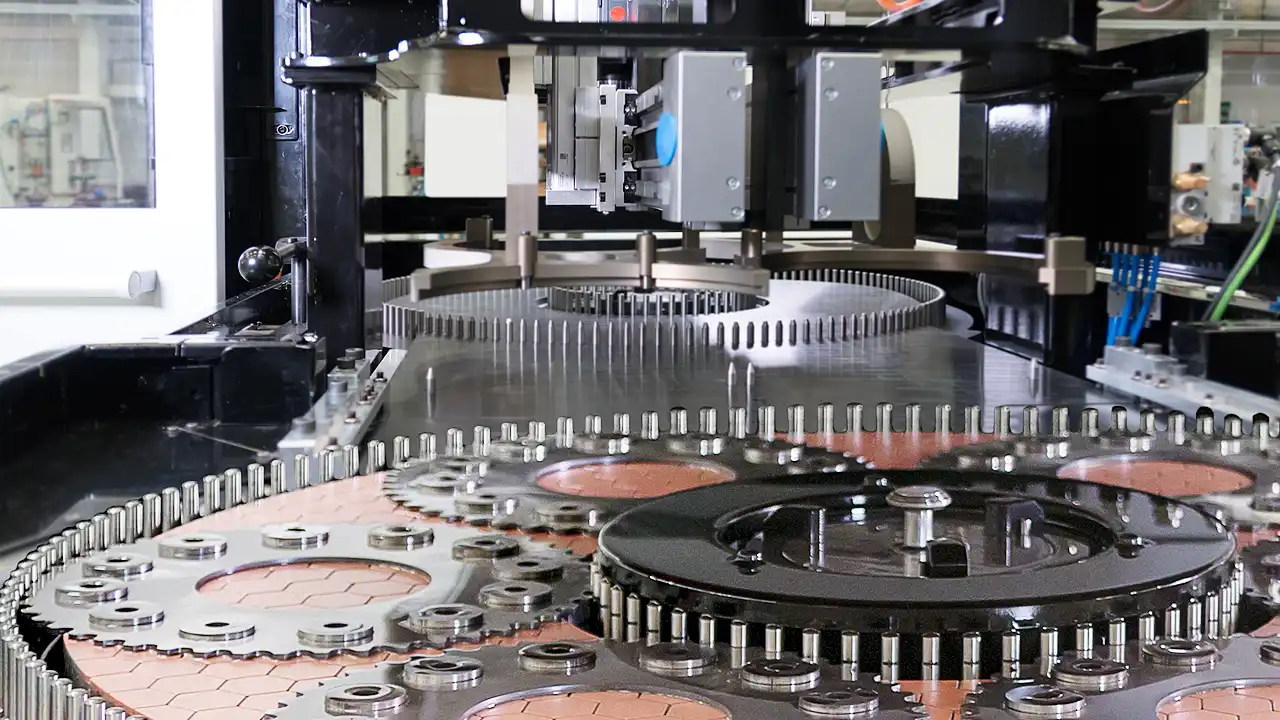

Spiro F7

Fine grinding in large-scale production

The flexible Spiro F7 fine-grinding machine is ideal for creating precise flat surfaces on workpieces made from a wide variety of materials.

- Memory for 192 programs

- Rigid machine concept

- User-friendly, thanks to visual-process control

| Technical data |

|

| Wheel diameter | 720 mm |

| Ring width | 200 mm |

| Maximum pressure | 1800 daN |

| Workpiece diameter | 5 – 220 mm |

| Workpiece thickness | 0,6 – 80 mm |

Spiro F12

For large workpieces

Our largest Spiro machine is designed to process workpieces with diameters of 6 mm to 420 mm and with special height, parallelism, and flatness requirements, all with high precision and cost-effectiveness.

- Energy-efficient, low-maintenance drive concept

- Very good accessibility

- User-friendly, thanks to visual-process control

- Flexible connection to different loading systems

Advantages of using a torque motor

- Energy efficient with very high initial torque

- No vibration due to geared components

- Direction change without backlash or loss of motion

- New machining sequences possible

- Maintenance-free operation

- No gear oil required

- Smaller footprint

- Maximum rigidity

| Technical data | |

| Wheel diameter | 1160 mm |

| Ring width | 341 mm |

| Maximum pressure | 3000 daN |

| Workpiece diameter | 6 – 420 mm |

| Workpiece thickness | 1 – 100 mm |

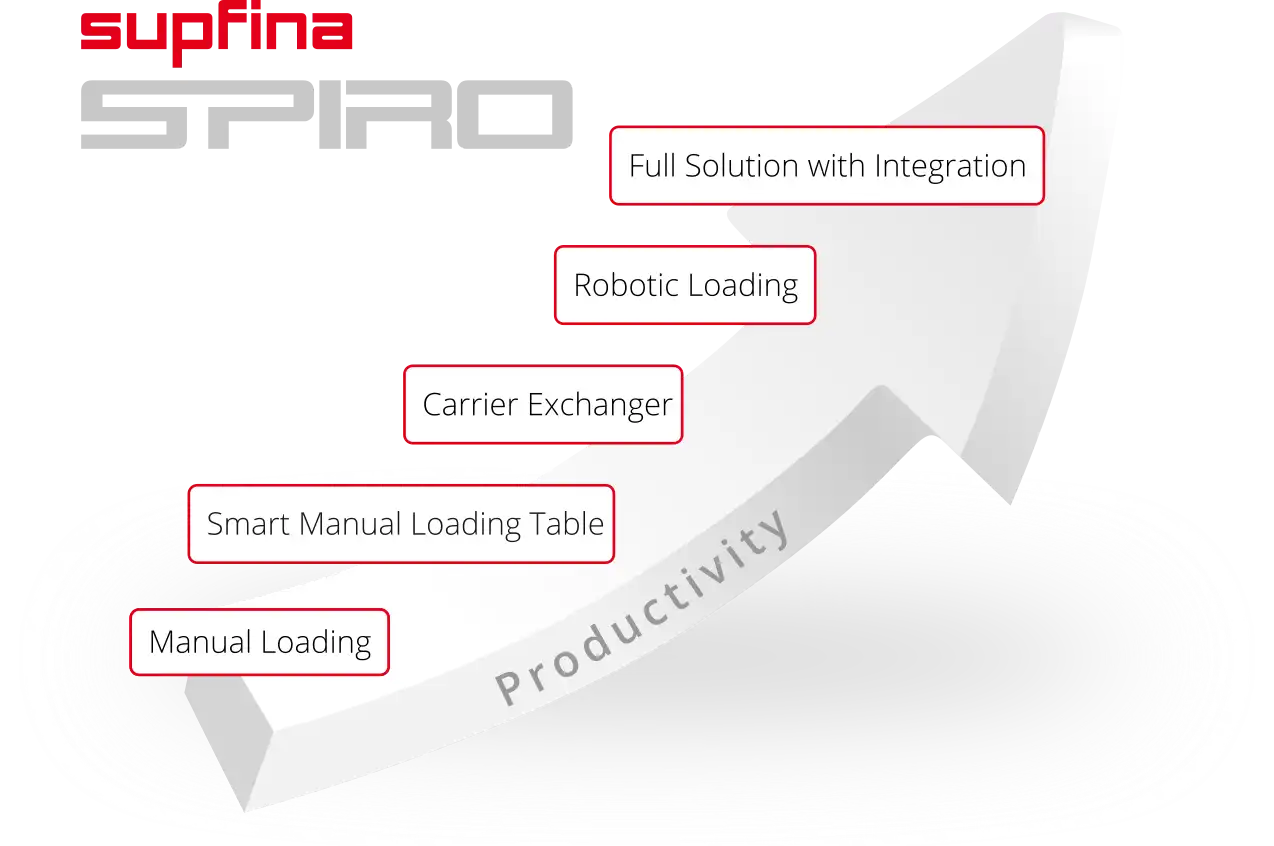

A range of options

Manual to fully automatic

We know your workflow is unique to your processes. Our wide range of loading and unloading options can meet any stringent needs.

From short cycle times to reduce downtime, short set-up times and flexible adaptation to different feeding systems and visual process control, Supfina finds your perfect solution for all these tasks.

Modern Controls

The user-friendly and intuitive operation, combined with visual process control, ensures consistently high precision.

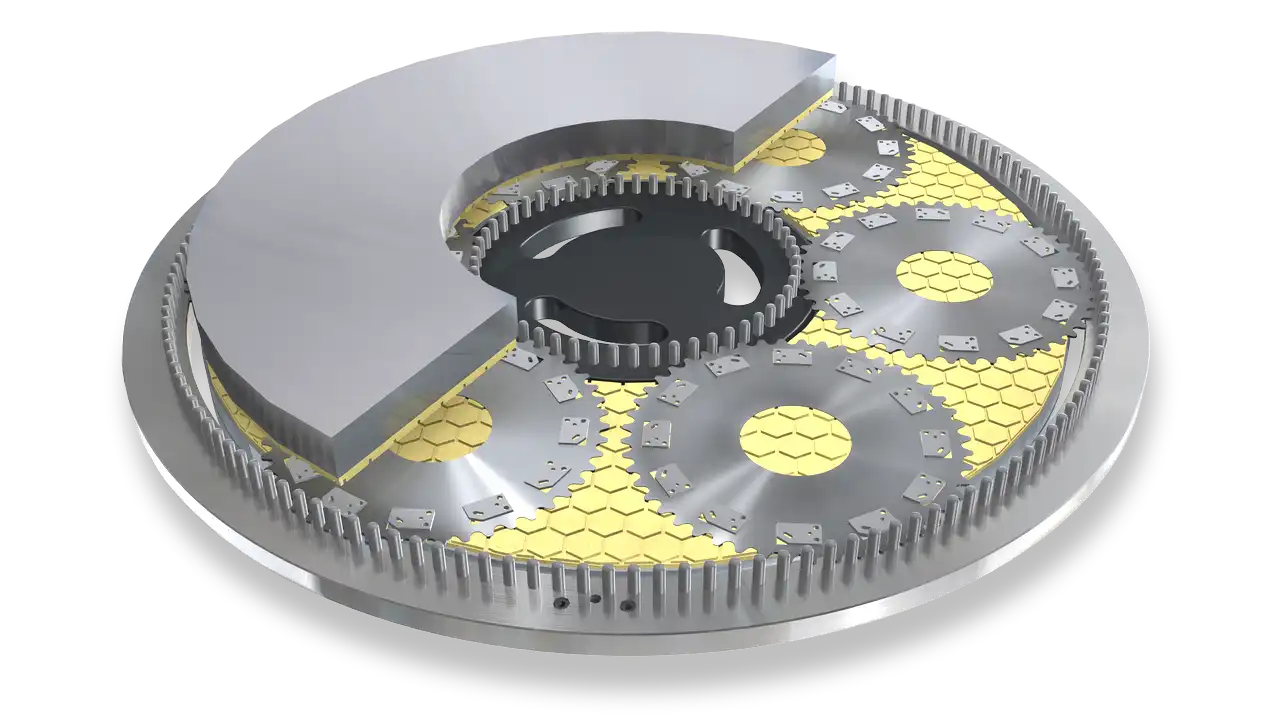

Automation

The utilization of a carrier exchange tool is just one of the many ways to improve efficiency automation in the Spiro.

Loading Tables

The Spiro F5 fine grinding machine can include the use of an optional loading table for manual loading and unloading purposes.

Case Study

Supfina recently partnered with The Timken Company with their complex automation needs, customizing a Spiro F5 with material handling robotics.

Case Study

the Swiss company MPS Micro Systems AG was looking for an opportunity to rapidly .expand its capacity in the manufacture of micro components without compromising on processing quality

Case Study

With the newly delivered Supfina Spiro F7 fine grinding machine, the precision parts specialist URBEN + KYBURZ AG, Switzerland, is expanding its product range and competitiveness.

Cutting Edge Technology

No matter the material, the job can be done to the most stringent requirements.

Brochure

See which Spiro fine grinding machine works for you, complete with technical information and specs.

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Are you looking for the right and economical solution for your manufacturing processes?

Deutsch

Deutsch  North America

North America  Français

Français  简体中文(中国)

简体中文(中国)