Solutions for Precision Mechanics and Optics

Grinding technologies for the finest components

Precision mechanical and optical components demand the highest standards in dimensional accuracy, surface quality, and process reliability. Supfina offers customized solutions for these demanding industries – using state-of-the-art grinding technologies and ultra-precise machines.

We provide hands-on, personalized consultation.

Upon request, we perform grinding trials using your original parts.

Request your individual solution today!

Typical Workpieces

- Watch glasses made from sapphire glass, mineral glass, and plastic glass

- Watch plates, barquettes made of brass and stainless steel

- Bridges and cocks for watch movements

- Watch dials

- Lens mounts for optical systems

- Precision discs and rings

- Pressure sensors

- Micro-optical components

- Ceramic parts for optical and medical technology

- Toothed wheel

- Bearing and retaining rings

- Disc magnets for sensor or actuator systems

- Miniature drive components

- Miniature couplings and gear parts

- Lens mounts, prisms, and plano optics

- Precision shims and spacers

- Valve plates for dispensing systems

- Microvalve components

Typical Materials

- Steel (hard/soft)

- Carbides

- Brass

- Ceramics

- PEEK

- Glass

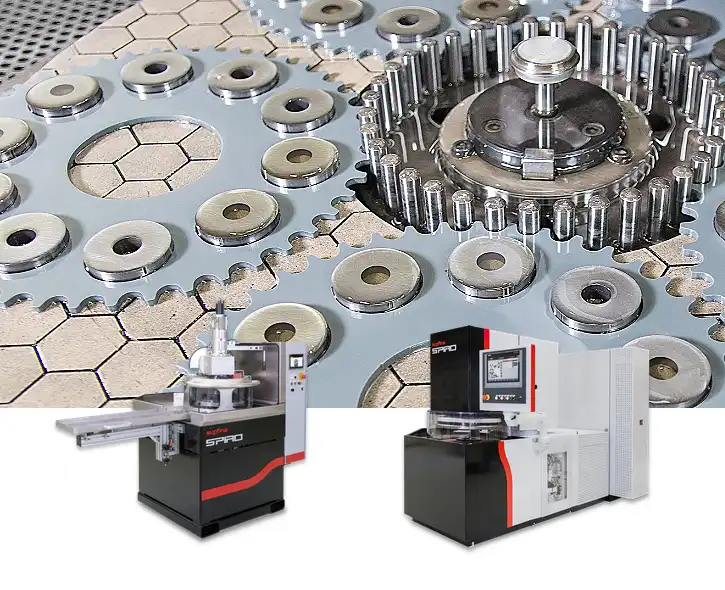

Fine Grinding

Highest precision for ultra-smooth surfaces

With the fine grinding machines Spiro F5 and Spiro F7, Supfina offers customized solutions for the ultra-precise machining of micro-mechanical and optical components. These machines ensure perfect flatness, outstanding surface quality, and high repeatability — even when working with sensitive materials.

Typical Workpieces

- Watch glasses made from sapphire glass, mineral glass, and plastic glass

- Watch plates and bridges

- Lens mounts and optical carrier plates

- Micromechanical precision parts

- Thin-walled precision components made of ceramic, glass, or non-ferrous metals

- Filter and sensor components with tight tolerances

Advantages

- Excellent flatness and surface quality down to the submicron range

- High dimensional accuracy and process stability even in series production

- Gentle processing of sensitive, brittle-hard materials

- Flexible adaptation to different part geometries and batch sizes

- Intuitive control and easy setup

- Optional automation for loading, measuring, cleaning, and drying

- Replacement of lapping processes to improve overall process efficiency

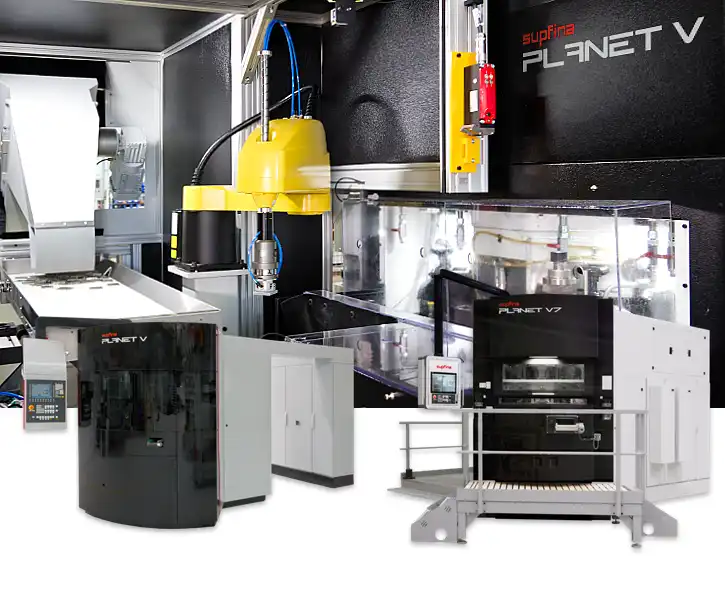

Double Disk Grinding

Efficiency in mass production

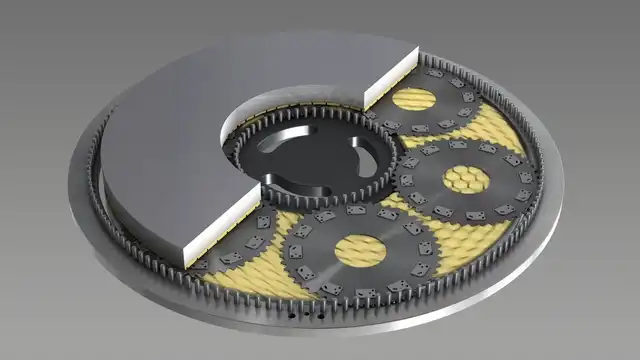

When high volumes and extreme precision are required, double-sided fine grinding with the Planet V4 and V7 is the ideal solution.

The Planet V series machines are designed for maximum precision and efficiency in series production. Innovative features such as the patented tilting navigation for fast grinding gap setup, integrated tool change assistance, and an intelligent dressing system ensure user-friendly and process-safe operation.

Thanks to an extremely rigid machine base, the highest throughput and tightest tolerances can be achieved reliably in just one pass – ideal for watch parts and other precision mechanical components made of steel, sintered metal, non-ferrous metals, plastics, ceramics, or glass.

For maximum productivity, the Planet V4 and V7 can be seamlessly integrated into automated production lines. Automated loading, as well as upstream and downstream processes like cleaning, brushing, or measuring, can be customized and smoothly incorporated.

Typical Components

- Precision parts such as piston rings, spacers, barquettes, etc.

- Stamped and forged parts

- Flat-parallel components made of steel, carbon, brass, etc.

Advantages

- Maximum productivity with simultaneous processing of both sides

- Highest material removal rates at shortest cycle times

- Rugged technology for continuous operation in mass production

Our Solutions

- Supfina Planet V4

- Supfina Planet V7

Highlights

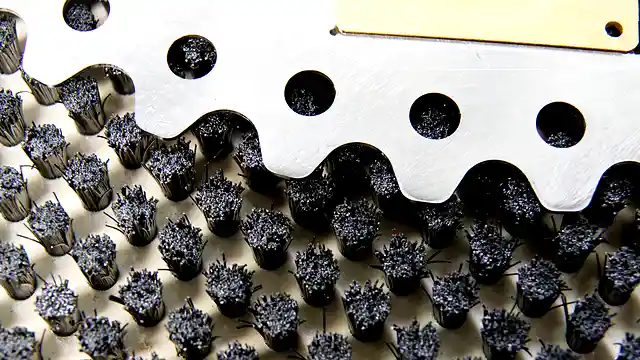

Automation

Supfina provides well-thought-out automation solutions for economical and process-reliable production.

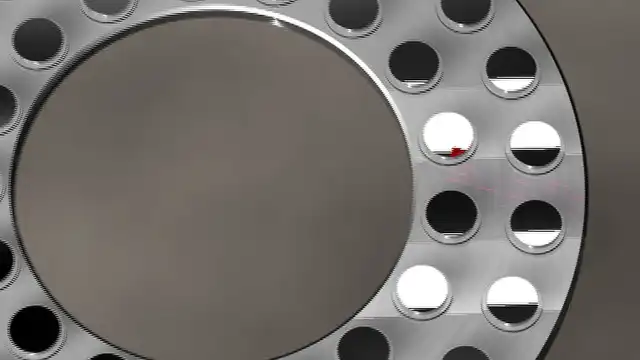

Gentle Handling

A specially bristled loading table reliably protects sensitive workpieces from scratches and damage – ideal for glass, brass, and fine surfaces.

Finest Watch Mechanisms

Gears, plates, and bridges – many of these components can be fine-ground or double-sided-flat-ground using Supfina technnologies ensuring economic efficiency and outstanding precision.

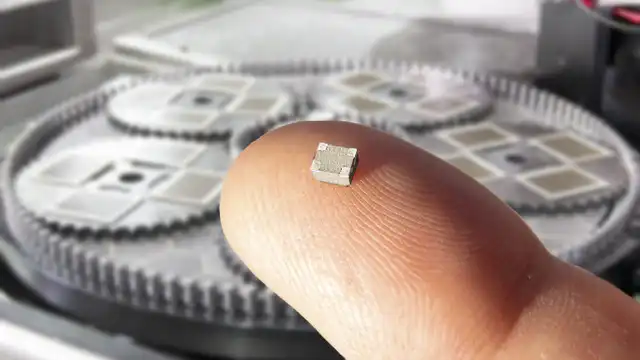

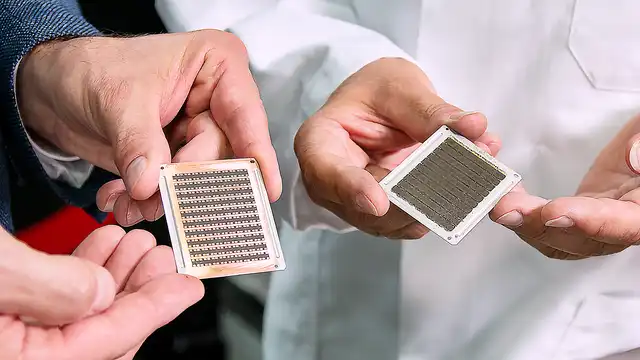

Smallest Dimensions

Even the tiniest components are processed safely and gently with Supfina machines – ideal for micromechanics and optics.

Know-how

Our experienced application team supports you from the first idea through to serial production.

Peripheral Processes

Supfina machines can be flexibly combined with upstream and downstream processes for end-to-end, process-secure production.

Fine Grinding

Technical aspects, advantages, and areas of application of fine grinding.

Case Study

Just the right precision for autonomous driving – With the Supfina Spiro F5, TDK produces innovative micro-inductors.

Double Disk Grinding

Technical aspects, advantages, and areas of application of fine double-sided grinding.

Are you looking for the right and economical solution for your manufacturing processes?

Deutsch

Deutsch  North America

North America  Français

Français  简体中文(中国)

简体中文(中国)