Solutions for efficient manufacturing

Automation today is more than just a trend — it is the key to stable processes, consistent high quality, and competitive production.

With decades of experience in precision and surface finishing, Supfina offers not only machines but complete solutions: from handling and interlinking, to robot-assisted machining and digital process integration.

Together, we design your intelligent production — reliable, efficient, and future‑ready.

Contact us today – request your individual solution

+1 401-294-6600 ·

Your benefits at a glance

- Increase productivity

ycle and setup times through automated workflows - Ensure quality

Precise, repeatable processes with controlled handling and sensor technology - Conserve resources

Less waste, reduced downtime, and optimized use of personnel

- Stay flexible

Modular systems that adapt to new parts, volumes, or processes - Shape the future

Interfaces for IoT and smart factory integration

Superfinishing

Autonomous manufacturing for maximum efficiency

Our autonomous production concepts enable continuous manufacturing without manual intervention — 24 hours a day, seven days a week.

All key operations are fully automated and executed 24/7 without operator input:

- Automatic batch and job changeover

- Self-adjusting setup and tool management

- Automatic replacement of consumable and wear parts

- Intelligent workpiece and material handling

- Data-driven control and integration into the production line

Fine Grinding

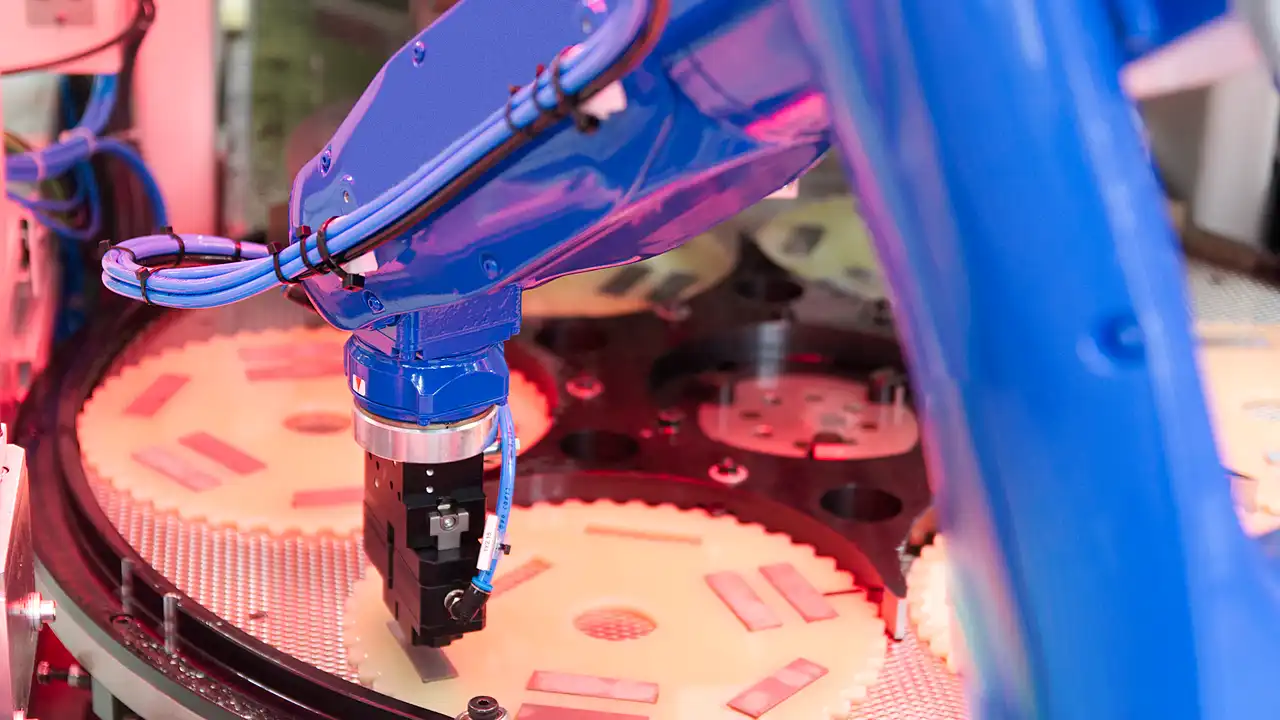

Optimized automation with the Spiro series

In fine grinding, automation of loading and unloading processes significantly increases efficiency and reduces production time.

Short auxiliary times, flexible feeding options, and visual process monitoring ensure productive serial manufacturing. The integration of robots and optical inspection systems provides a high level of automation and minimizes error.

Your benefits at a glance

- Fully automated loading and unloading

- Flexible feeding and loading systems

- Intelligent process monitoring

- Short non-productive times

Double Disk Grinding

Automated grinding of mass-produced flat parts

With the Planet V series, Supfina offers a high-precision solution for double-disk grinding of mass-produced flat components.

Thanks to innovative automation technologies and flexible interlinking options, production processes can be designed for maximum efficiency and significantly reduced manufacturing costs. The machines feature high cost-effectiveness, short cycle times, and easy integration into existing production lines.

Your benefits at a glance

- Automated loading and unloading

- Flexible interlinking solutions

- Short cycle times

- High cost efficiency

Manufacturing Cells

Robotic Manufacturing for Maximum Flexibility

Our robotic manufacturing cells provide a modular and scalable solution for your production processes. By integrating industrial robots, various manufacturing steps such as loading and unloading, measuring, machining, and inspection can be carried out efficiently and with maximum flexibility.

These cells can be seamlessly integrated into existing production lines or operated as standalone units./p>

Your Benefits at a Glance

- Modular and scalable

- Flexible processes

- High availability

- Cost-effective and productive

Highlights

Video

Discover Supfina’s automation solutions for spherical components and flat bearings.

Brochure

Further information on autonomous manufacturing with Race Modular.

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Are you looking for a flexible, modular and economical solution for your manufacturing processes?

Deutsch

Deutsch  English

English  Français

Français  简体中文(中国)

简体中文(中国)