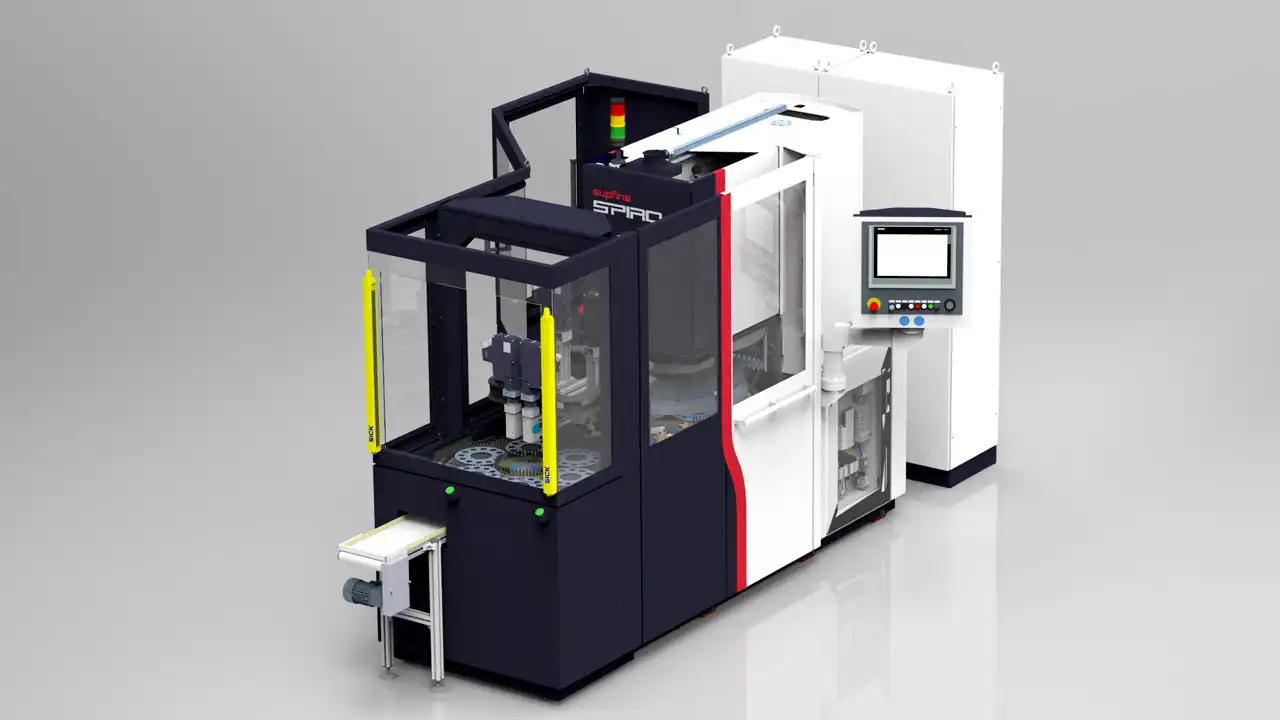

Loading Systems

for the Spiro

We know your process is unique. Our wide range of loading and unloading options can meet any stringent needs. From short cycle times to reduce downtime, short set-up times and flexible adaptation to different feeding systems and visual process control, Supfina finds your perfect solution for all these requirements.

Flexible Loading Systems

Automated Carrier Loading System

A loading system from the Supfina Spiro can help make your fine grinding process even more efficient – with an added option of partially autonomous production. Flexible in setup, productive in use.

- Quick set-up

- Flexible feeding options

- Visual process control

- Expedited cycle times

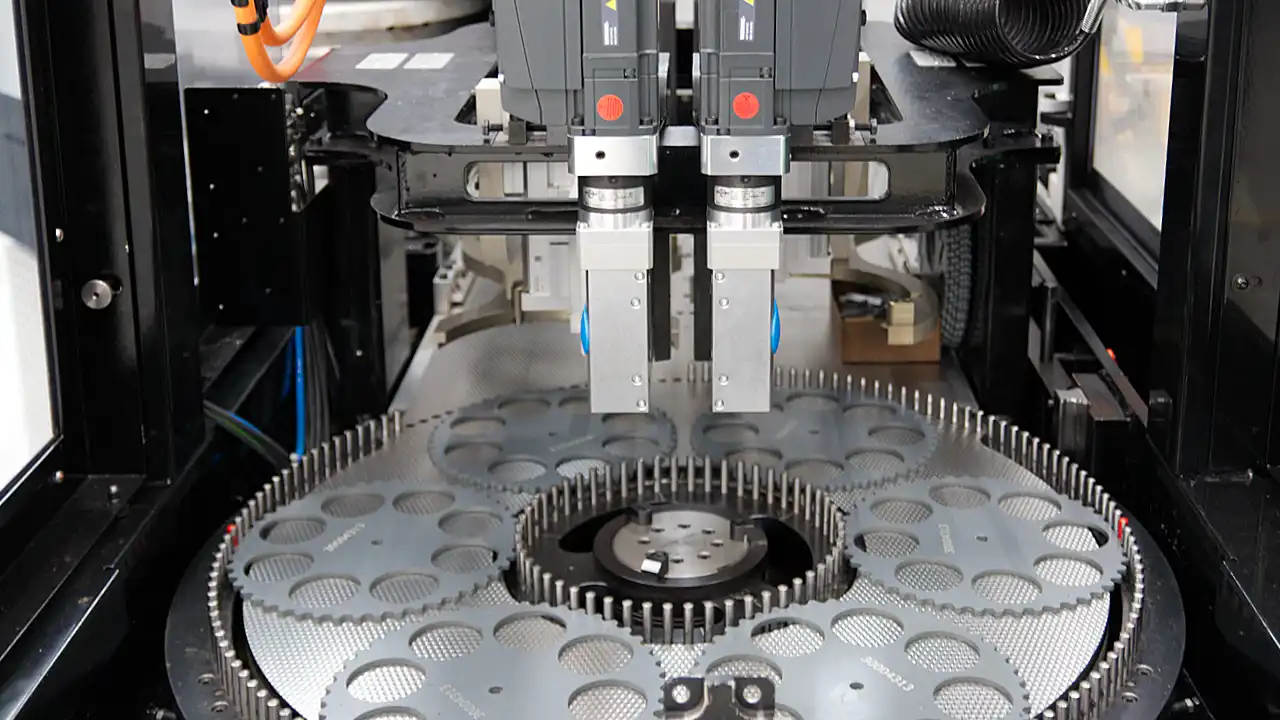

Spiro with Robot Assistance

For an enhanced, hands-off experience. Partially automatic loading and unloading of a Spiro F5 with robotic support. A visual inspection camera monitors the process for any inaccuracies and inefficiency.

Benefits of a robotic automated system like this include:

- Cost reduction

- Error reduction

- Increased throughput

- 24/7 use possible

- Flexibility through robot control

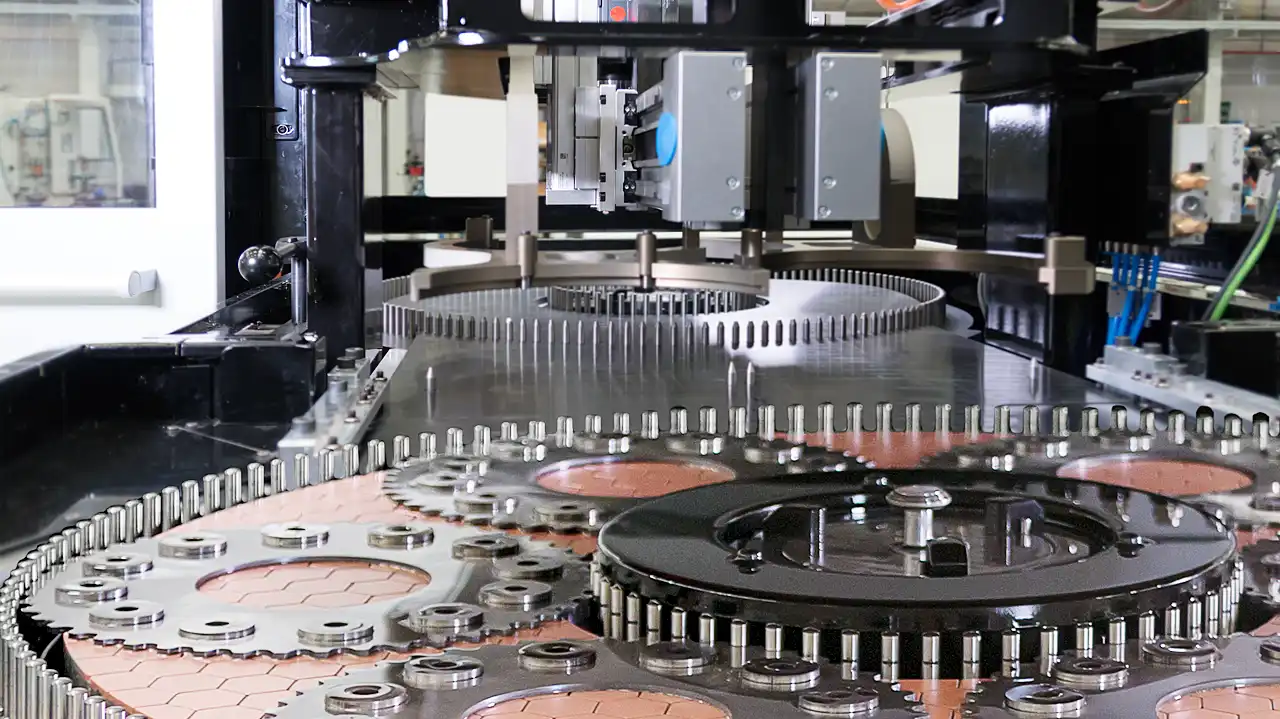

Material Handling Robot

The workpieces are inserted into their loading trays by a robot and removed again after fine grinding. With optical monitoring, the robot can be guided and the correct loading can be controlled.

Benefits of a material handling robot include:

- High degree of automation

- Consistent cycle times

- visual process control

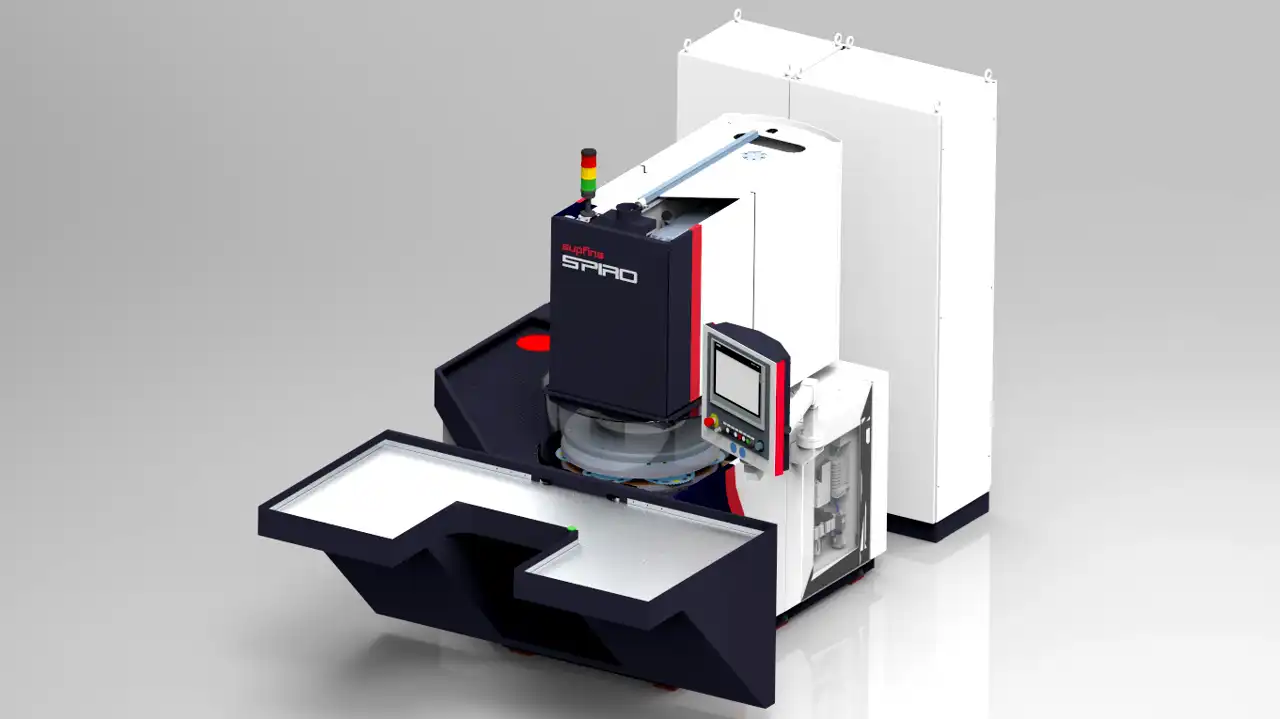

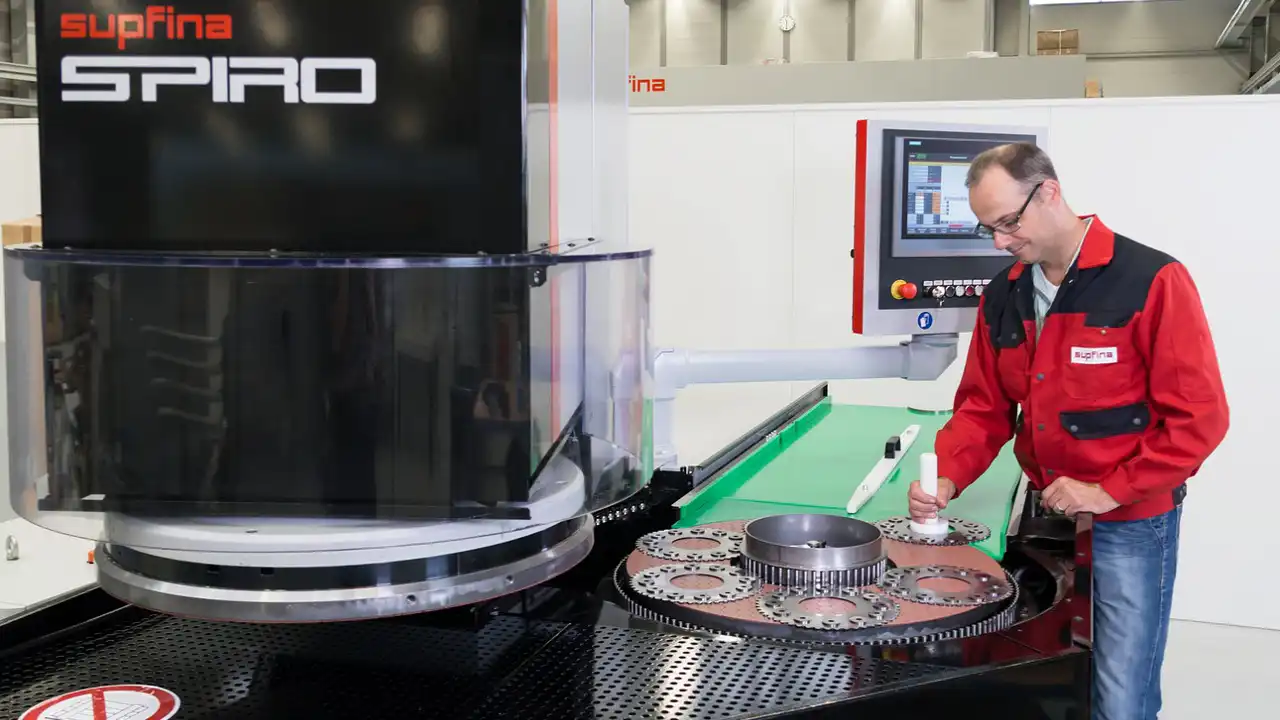

Manual loading table

Allows quick manual loading of the workpiece holders.

- Expeditious loading of the workpiece holders

- Effortless loading of the system due to a seamless transition to the grinding wheel

- Expansive area for loading and unloading of carriers

Spiro F7, manual loading/unloading

Two separate sliding areas allow fast loading and unloading. Equiped with plastic running rails for sensitive workpieces.

Loading of sensitive materials

This loading table is equipped with special brushes which can protect even the most sensitive workpiece surfaces.

- Any workpiece properties

- Ease of loading with our proprietary sliding mechanism

- Expansive area for synchronous loading and unloading of workpiece holders

Spiro F5, manual loading/unloading

Reliable, durable, and functional loading tables:

- Robust stainless steel

- Separate areas for loading and unloading

The finished workpieces can be pushed out of the grinding area on one side, while new workpieces are fed simultaneously on a second side.

Modular systems are available for manual and automatic loading, which can be individually adapted or extended by newly developed components based on your specific needs.

The new automated carrier exchanger system from Spiro will help make your fine grinding process even more efficient – all the way to fully autonomous cycles. Flexible in setup, productive in use.

Are you looking for a flexible, modular and economical solution for your manufacturing processes?

Deutsch

Deutsch  English

English  Français

Français  简体中文(中国)

简体中文(中国)