Ball machining

Superfinishing of spherical components

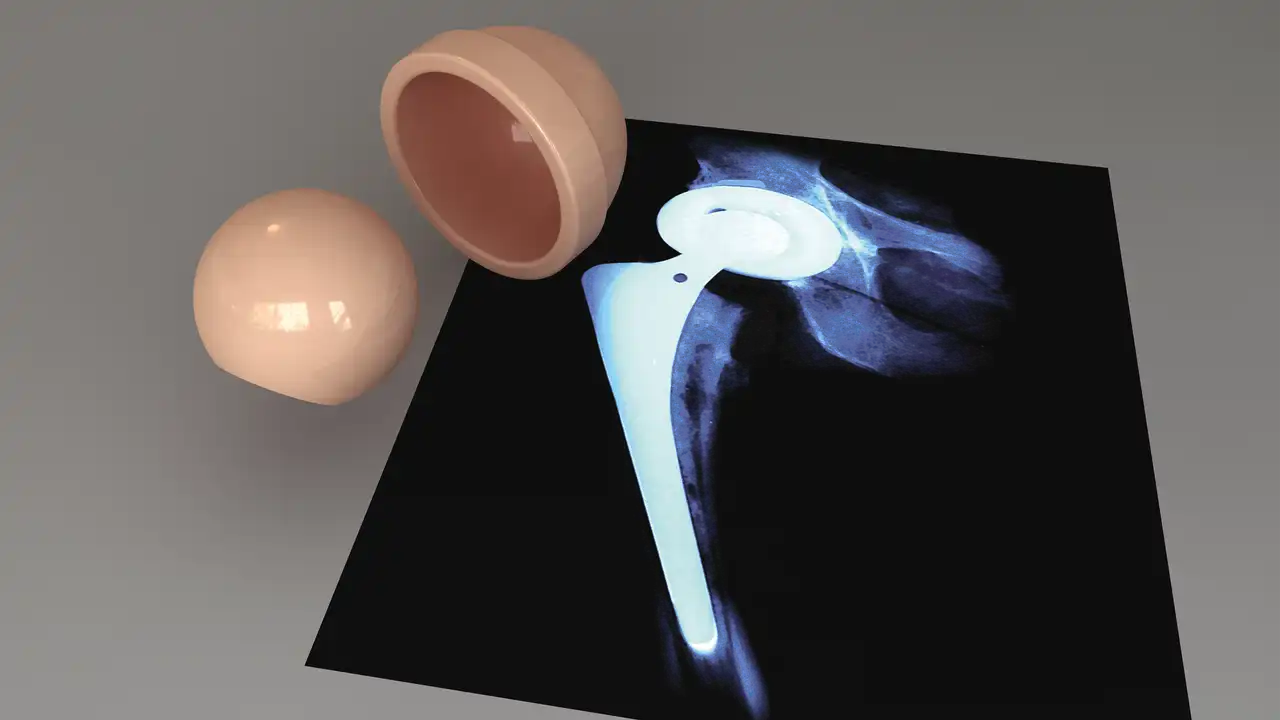

Spherical plain bearings and spherical components are used in diverse areas: they are installed in a wide variety of ways in the aerospace industry as well as in the automotive and agricultural industries. In all areas, however, these parts are subject to the highest quality requirements, as they must function perfectly despite high loads.

Precise machining and production are therefore imperative. In addition, long-term process reliability and low cycle times are of utmost importance for the cost-efficient production of the required quantities in constantly growing industrial sectors.

LCM TS

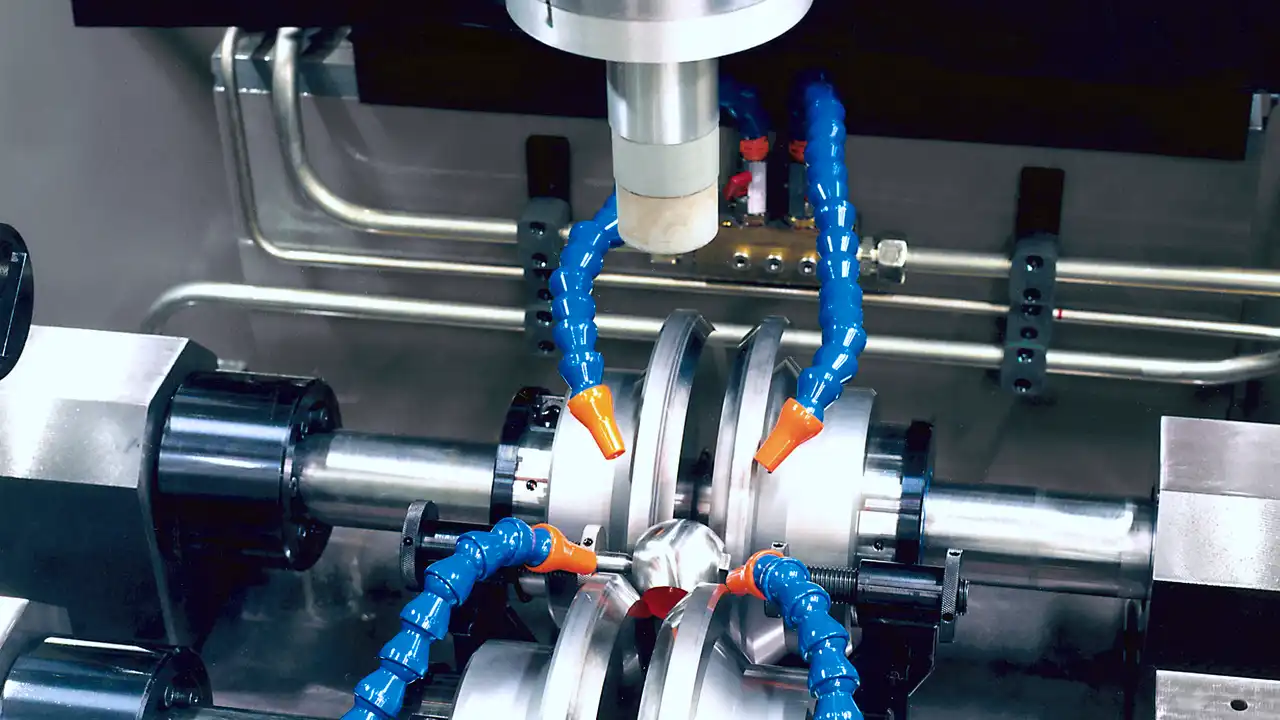

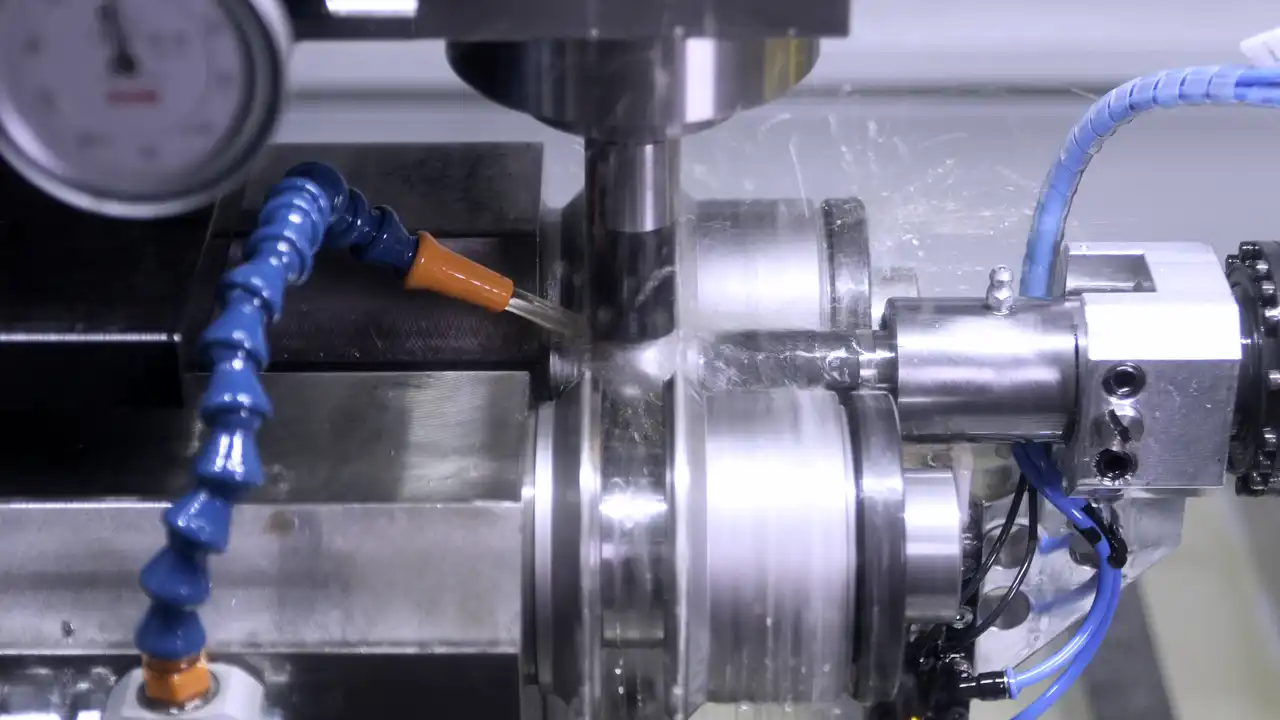

Machining of spherical plain bearings

with robotic feeding

Based on our decades of experience in superfinishing and the automation of manufacturing processes, our solutions meet these demands with precision.

In cooperation with our customers, we develop systems that meet any specific requirements.

In this way, maximum accuracy and consistent surface quality are achieved, even for individual components, with low unit costs.

- Increase of OEE through automation

- Fulfillment of the required qualities

- Increase of material carrying capacity

- Improvement of microgeometry

- Optimization of surface structure

- Competitive advantage through high flexibility

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Face

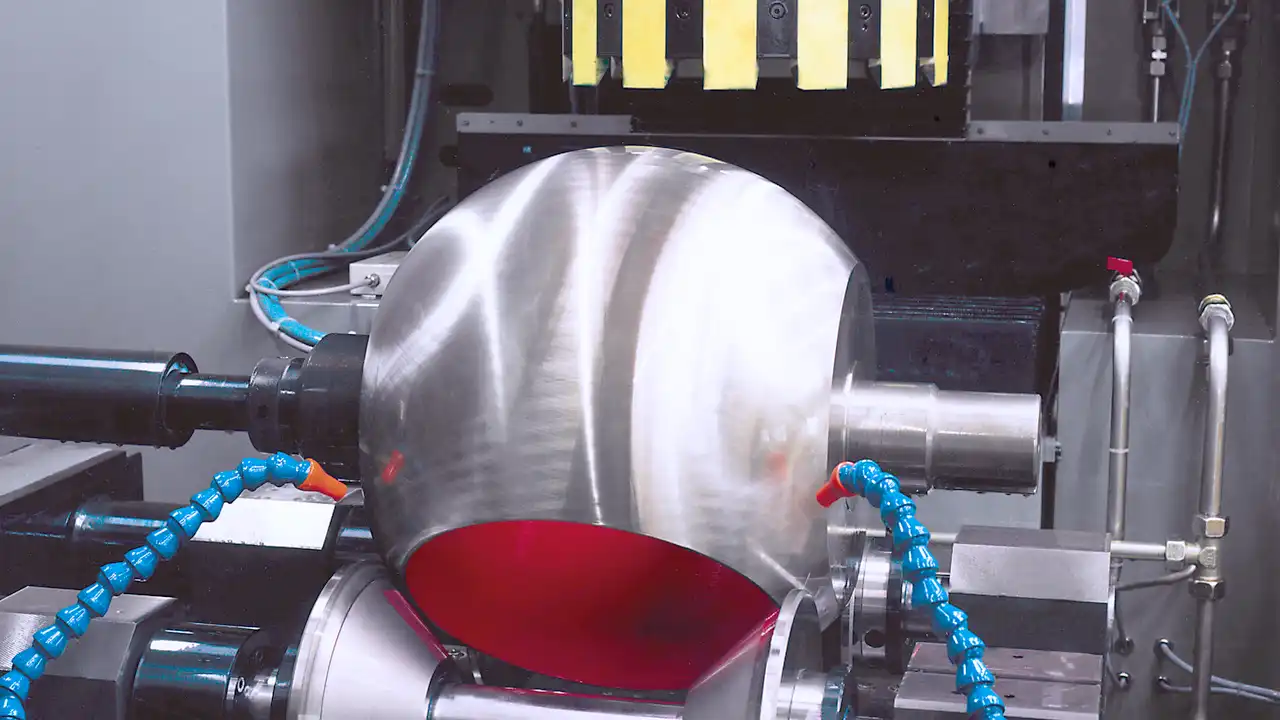

Spherical superfinishing with highest precision

The rotary transfer machine Supfina Face generation: a flexible rotary transfer solution with a unique machine structure allowing the highest production volumes while also being flexible for maximum cost efficiency.

The development was based on the general standards of: cost efficiency, flexibility, safety and environment.

- Vertical spindle orientation for highest precision

- Fast setup processes through software-supported adjustment of the machining unit

- Bridge construction for maximum stiffness

- Optimal accessibility for retooling and maintenance tasks

- External loading by robots gantry systems possible

- Integrated loading systems available

- Integrated fire extinguishing system for optimal safety

- Maximum energy efficiency by omitting cooling systems

- Supfina IQ-Finish process control for continuously best results and high quality

- Best possible work ergonomics

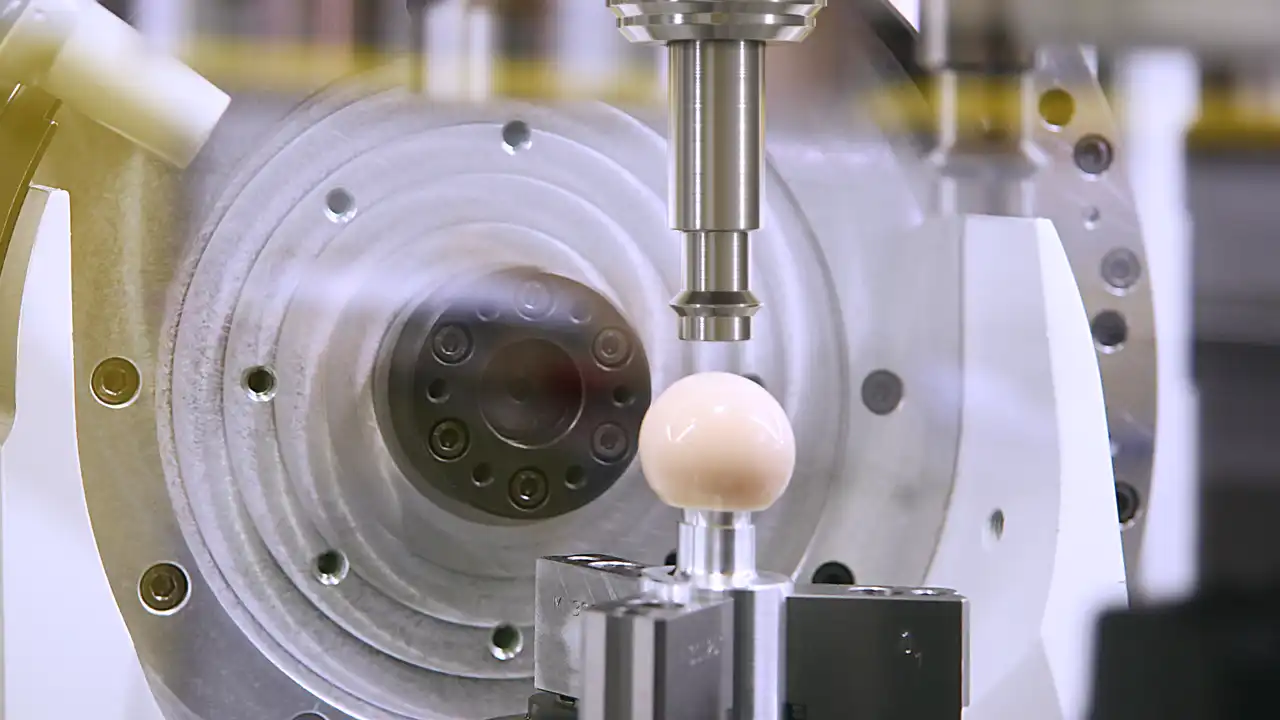

Medical technology

Supfina's superfinishing technology also gives ceramics the desired surface finish in top quality.

Valve technology

For maximum tightness and load: Superfinish from Supfina.

Spherical bearings

Highly automated solutions for spherical plain bearings and rod ends.

Supfina solutions for ball machining

Are you looking for the right and economical solution for your manufacturing processes?

Deutsch

Deutsch  North America

North America  Français

Français  简体中文(中国)

简体中文(中国)