Flat finishing

Uniquely flexible

With the Face series, Supfina provides the ultimate solution for versatile flat finishing for medium and large workpiece volumes – fast and flexible.

Components from the fields of injection technology, transmission components, hydraulic or engine parts can be produced with the tightest tolerances in the tenth micrometer range and with the highest reliability and efficiency.

Nano

Compact and precise

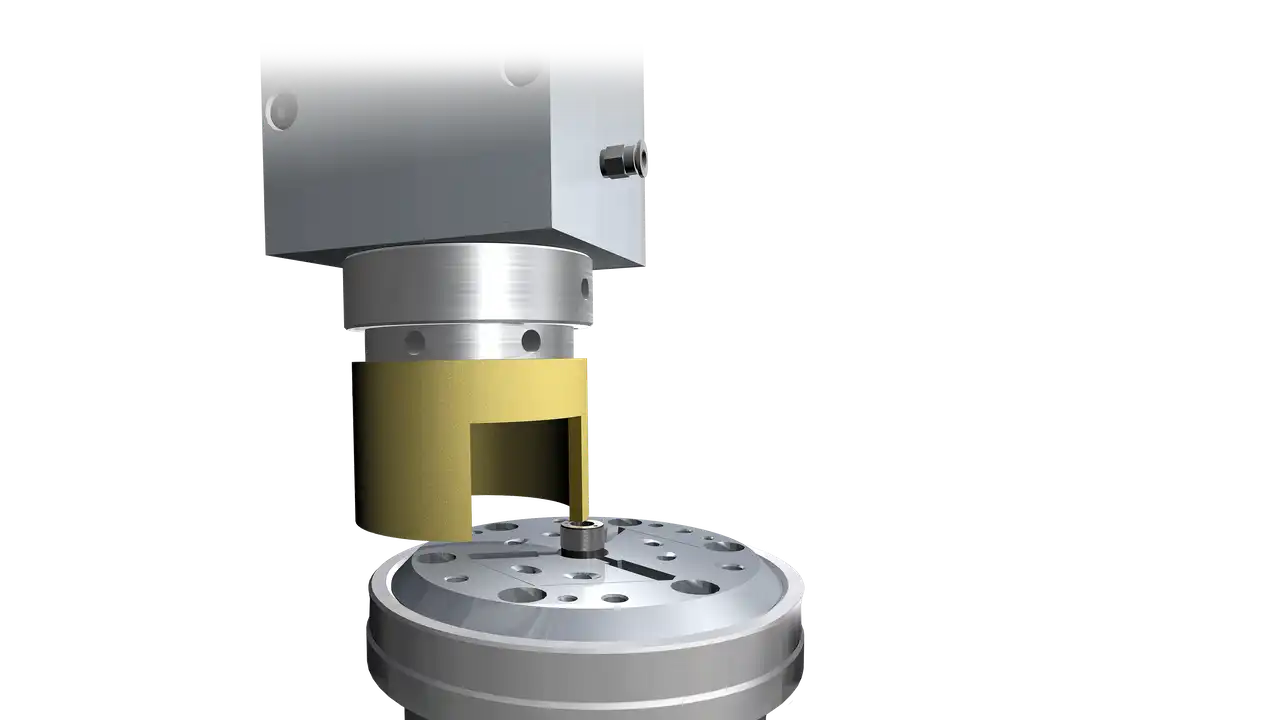

The Supfina Nano machine series covers a wide range of flat finish processing needs.

Transmission components, engine parts, components from the fields of injection technology, hydraulic or engine parts can be produced with the tightest tolerances in the tenth micrometer range and with highest reliability and efficiency.

- Automatic adjustment of the cup wheel center line

- Simple tool change

- Suitable for use with conventional and super abrasive tools (CBN/diamond)

- Efficient adjustment for new tools

- Universal loading and unloading: manually, with a portal loader or robot systems

- Optimal accessibility

- Moveable and flexible in-process measuring system

- Modern process adjustment for optimal and consistent quality results

- Angle adjustment for spherical processing

| Technical data | |

| Workpiece length | 150 mm |

| Workpiece diameter | 100 mm |

| Machining diameter | 50 mm |

| Superfinishing attachments | 1 – 2 |

| Spindle speed rpm | 30000 |

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Face

Flat Finishing for changing requirements

Supfina Face – the new rotary transfer machine generation: a flexible rotary transfer solution with a unique machine structure allowing the highest production volumes while also being flexible for maximum cost efficiency.

The development of the Face series was based on the general standards of: cost efficiency, flexibility, safety and environment.

- Vertical spindle orientation for highest precision

- Fast setup processes through software-supported adjustment of the machining unit

- Bridge construction for maximum stiffness

- Optimal accessibility for retooling and maintenance tasks

- External loading by robots and gantry systems possible

- Integrated loading systems available

- Integrated fire extinguishing system for optimal safety

- Maximum energy efficiency by omitting cooling systems

- Supfina IQ-Finish process control for continuously best results and high quality

- Best possible work ergonomics

| Technical data | |

| Workpiece length | up to 200 mm |

| Workpiece diameter | up to 200 mm |

| Machining diameter | up to 150 mm |

| Superfinishing units | up to 7 |

| Chuck | up to 8 |

| Process integration | Flat finishing with cup wheels, brush deburrers, size measurement, tape finishing |

Technology

Technical aspects, advantages and areas of application of flat finishing

Application examples

Do you have a special workpiece or material to machine? For many applications we already have suitable machining examples, for all others we will gladly provide sample machining. Please contact us.

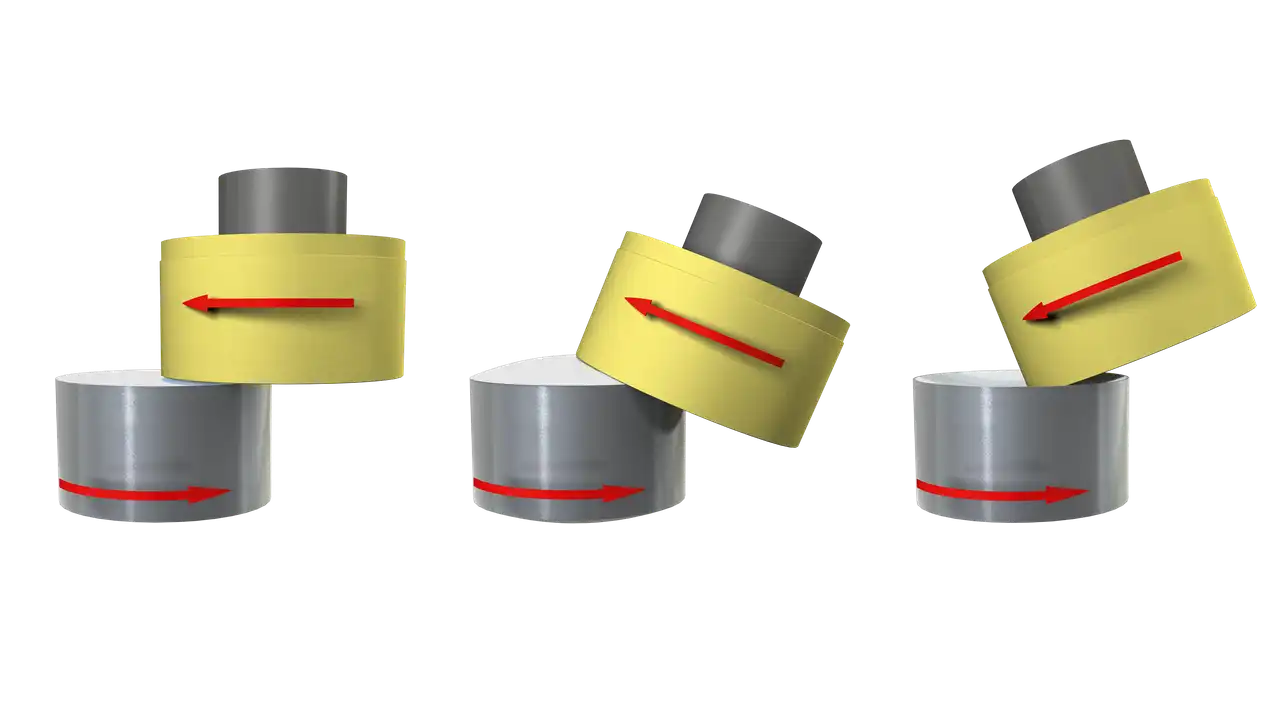

Flat · Convex · Concave

The flat finishing process is not only used for producing flat surfaces it can be used for convex and convex surfaces as well. Due to an angular adjustment of the cup wheel spindle, a precise spherical surface can be produced.

Since commissioning a year ago, the Supfina Face flat finishing machine has been producing at the XinYa GreenPower plant with the highest quality and reliability.

“We are very satisfied with this machine.”, Mr. Zhuang Furu, General Manager of ShanDong Xinya GreenPower Fuel Injection System Co. Ltd., „It has been running stably since it was put into operation for more than a year meeting our requirements for flat superfinishing quality and output.”

XinYa GreenPower is a leading enterprise specializing in R&D and manufacturing of electronically controlled high-pressure common rail fuel injection system and related parts.

With the Face series, Supfina provides the ultimate solution for versatile flat finishing for medium and large workpiece volumes – fast and flexible.

Components from the fields of injection technology, transmission components, hydraulic or engine parts can be produced with the tightest tolerances in the tenth micrometer range and with the highest reliability and efficiency.

Are you looking for a flexible, modular and economical solution for your manufacturing processes?

Deutsch

Deutsch  English

English  Français

Français  简体中文(中国)

简体中文(中国)